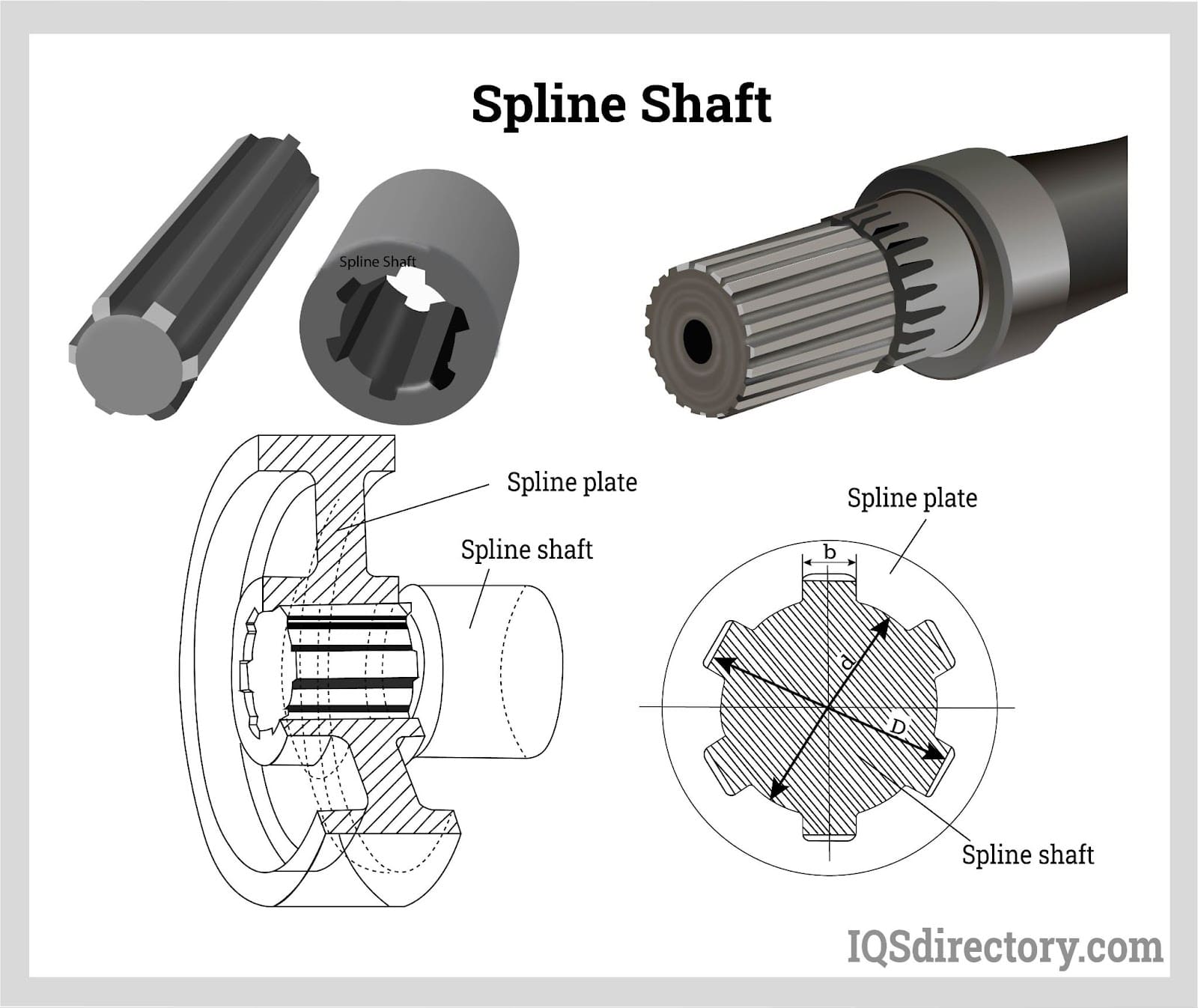

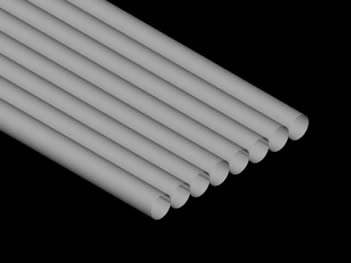

A spline shaft (a.k.a. splined shaft) is a rotating machine element that transfers power from one part to another using grooved shafts that interlock with mating pieces. The grooves provide protruding keys that fit into paired bushings, bearings, bores, gears, or other components made especially to mate with shaft splines. Read More…

Pioneer Broach Company is premier vendor of quality rotary broaching cutting tools. We specialize in custom spline, serration and hexalobular shaped rotary or wobble broaches, and also offer a complete line of standard hex and square rotary broach tools. Our new rotary broaching toolholder is designed for all modern CNC machines, mills and lathes.

Apex Broaching Systems is a worldwide supplier of standard broaching machines, special purpose broaching machines, fixturing, automation, and cutting tools. We have over 69 years of innovative engineering, skilled craftmanship, quality manufacturing, assembly, and customer satisfaction. All of our products are made here in the USA. Contact us today and tell us how we can meet your demands!

Diamond Broaching Service LLC showcases its value to its customers and the industry through quality customer service. The new team of Engineers and Machinists continue to provide the same high quality broaching services that our customers have depended on for over 70 years. With over 400 Broaching Tools in our inventory, we can respond quickly to provide the following shapes in just about all...

Since 1981, Universal Broaching has made a name as a dependable broaching job shop that offers quality products, impeccable service & competitive pricing for all broaching needs, no matter the size of the run. We offer horizontal internal broaching, vertical surface broaching, blind hole keyseating, broach sharpening, reconditioning & repair, and engineering & manufacturing of broaches & fixtures.

More Spline Shaft Companies

Spline shafts are also utilized to convey torque in systems involving both linear and rotary drives.Through the addition of these grooves, spline shafts offer greater rotational resistance in anti-rotation applications when compared to more conventional drive shafts.

Working Principle of a Splined Shaft

Spline shafts are created in order to optimize the amount of contact between the shaft surface and the interlocking components. A spline shaft locks into place when used for anti-rotary applications, stopping rotation while still permitting linear motion. The interlocking bearing or gear will frequently slide up or down the shaft when functioning as a linear guard to ensure accurate linear movement without permitting unwanted rotation. Splined shafts revolve while being interlocked with a gear, bearing, or other mechanism when employed in rotary applications. High levels of force or torque can be transmitted between mechanisms thanks to the close contact between matched surfaces. Different splined shaft designs are available that are made to meet the requirements of various power transmission applications.

Types of Splined Shafts

Depending on the size, spacing, and shape of the grooves and keys on the shaft and mated components, splined shafts come in a wide range of configurations. The most typical kinds of splined shafts are:

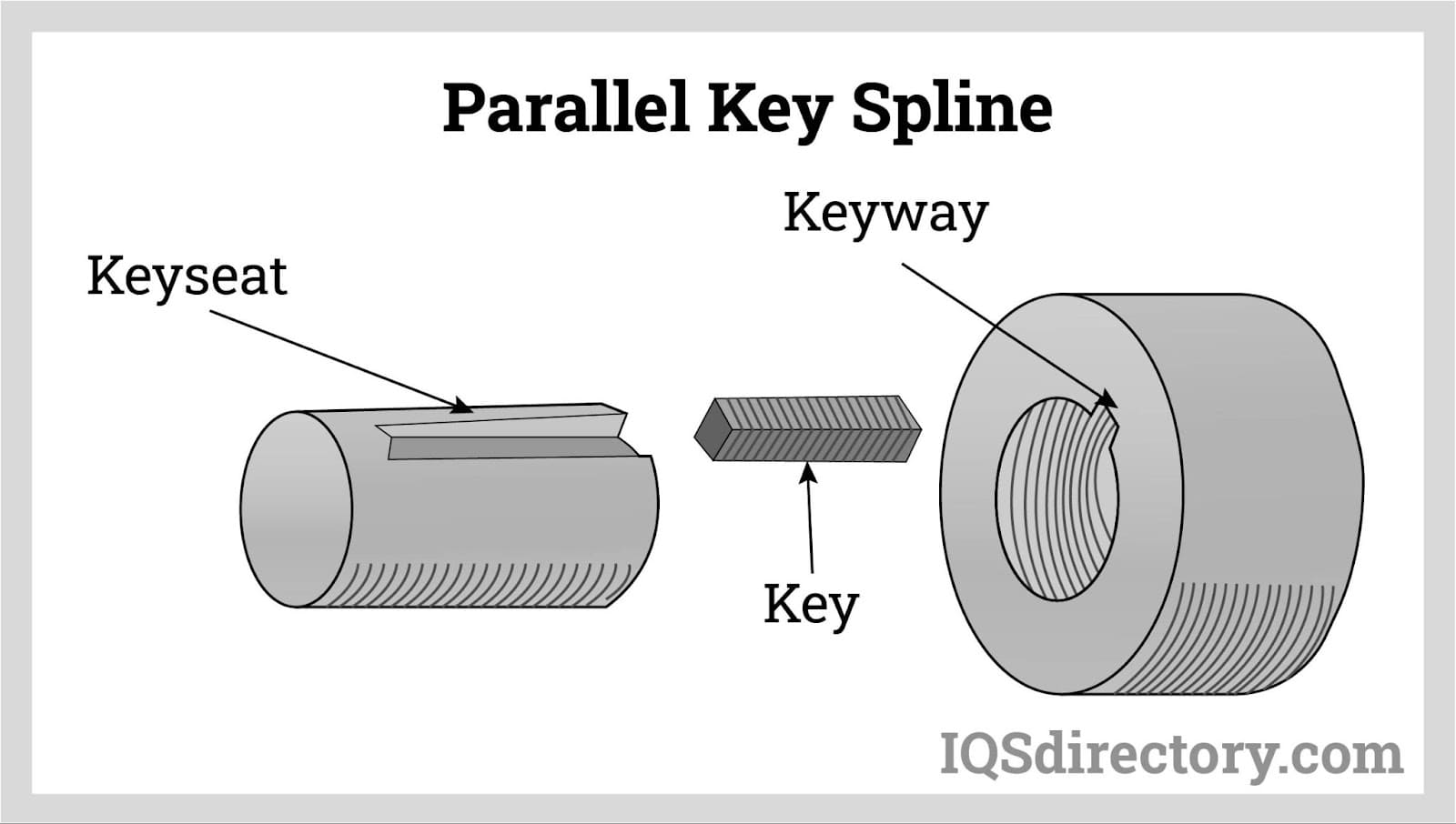

Splined Shafts with Parallel Keys

Keys are a component inserted between a shaft and the hub of another mechanism in order to prevent rotation while still allowing a linear sliding motion along the shaft. Parallel keys and grooves in splined shaft designs are square-shaped, with their profiles parallel to the shaft's axis. This design is appropriate for load-bearing applications that demand smooth motion.

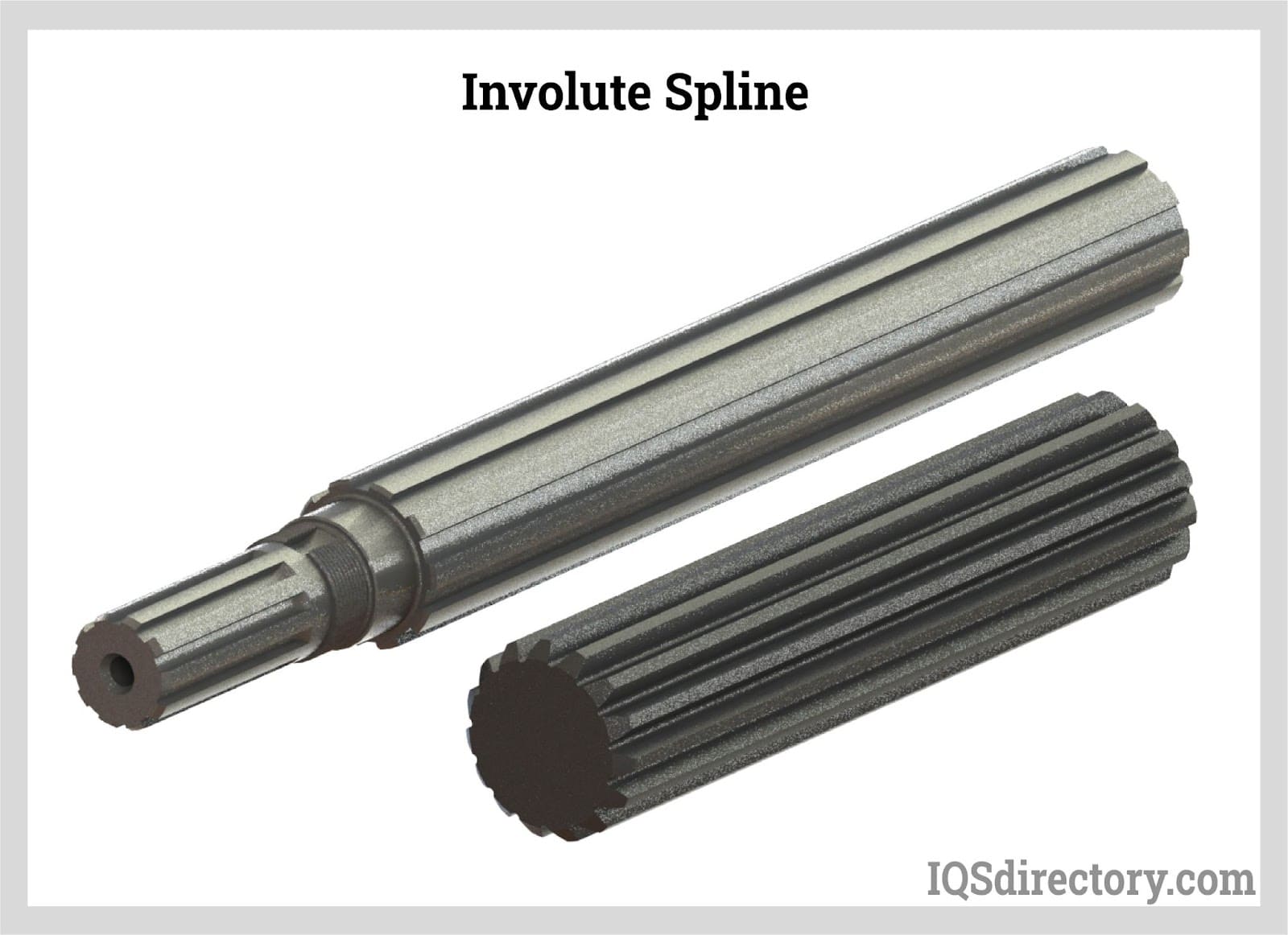

Involute Spline Shafts

This version of a spline shaft uses involute splines featuring short and evenly spaced teeth which enable greater strength with more evenly distributed stress. Due to their propensity to self-center, increased structural strength, and simplicity of adjustment to a variety of dimensions, involute spline shafts are one of the most widely used varieties of spline shafts. Available types include:

- Major diameter fit splines measure the space between the major diameter of the internal part to the outside diameter of the external part. Generally, the less clearance/difference between the two, the better as a negative value means the parts won’t fit and too much value means the parts fit too loosely affecting their efficiency.

- Fillet root involute splines have a smooth curve between the teeth and the root diameter.

- Flat root involute splines may not have the smooth curve and will have a flat portion between teeth.

Materials Used for Making Spline Shafts

Spline shafts require a lot of pressure for their energy transmission applications and might warp and shatter after prolonged use. Therefore, it's critical that the user has the appropriate spline shaft material for their unique application.

Alloy steels: Alloy steels are frequently used in the production of splined shafts. Alloy steels are iron-based alloys, often known as ferrous alloys, that contain a combination of other metals to improve properties including ductility, hardness, toughness, and tensile strength. In addition to iron, alloy steels may also contain copper, nickel, molybdenum, chromium, and nickel.

Aluminum alloys: Aluminum alloys have a higher strength-to-weight ratio than steel but are less dense, making them a great lightweight option for many applications. They can function well under intense pressure and are harder than some steels. Additionally, when exposed to moisture, aluminum alloys are corrosion-resistant and won't rust.

Carbon steel: Iron in carbon steel contains up to 1.7 percent carbon. This substance creates components that are exceptionally accurate and robust.

Stainless steel alloys: These alloys combine the strength of iron with chromium (and other elements). In regards to spline shafts, stainless steels’ ability to withstand corrosion sets them apart. Chromium, a component of these alloys, interacts with air to form an oxidized coating that shields these materials against corrosion and rust. Additionally, stainless steels have a high tensile strength and are sturdy, long-lasting, and wear-resistant.

Splined Shaft Production Process

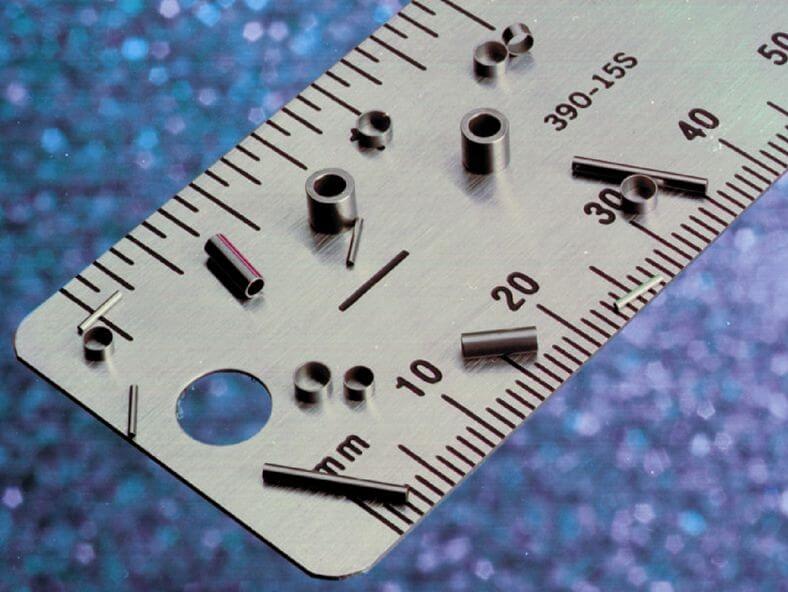

Splined shafts are frequently machined using sophisticated techniques to produce extremely precise teeth and grooves. Precision in spline machining is essential to ensuring that the shaft fits tightly against adjacent parts for the best possible power transmission. Spline shafts are mostly produced using one of two methods:

CNC (computer numerical control) turning: CNC turning makes use of lathes and cutting instruments that are controlled by CNC software. Even for exceedingly complex components, the shaft may be machined with excellent precision by rotating the tools and workpiece on up to 5 axes. Fine cuts can be made at almost any angle with speed unsurpassed by other, more conventional techniques when using this multi-axis operation.

CNC milling: Like CNC turning, CNC milling precisely removes excess material to produce the desired groove and tooth shapes while the workpiece is held in a lathe. Companies can produce splines, gears, bearings, and other precision components with incredibly tight tolerances thanks to the use of 5-axis CNC milling machinery.

Splined Shaft Applications

In addition to providing outstanding control and a consistent load distribution along the whole spline groove, splined shafts are designed to endure high-speed rotation. Splined shafts can transmit enough torque to power heavy-duty, load-bearing equipment and high-speed applications. Higher speeds and more reliable load transmission are made possible by evenly distributed force without running the risk of catastrophic part misalignments. Splined shafts are essential to a wide range of applications, including manufacturing and industrial facilities, and can be found in personal vehicles, aerospace machinery, and public transportation. Splined shafts frequently appear in the drivetrains of automobiles, where they convert rotary motion into linear motion.

Choosing the Right Spline Shaft Manufacturer

To make sure you have the most productive outcome when purchasing Spline Shafts from a Spline Shaft Manufacturer, it is important to compare at least 5 Companies using our Spline Shaft directory. Each Spline Shaft Manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Spline Shaft company website using our patented website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple Spline Shaft companies with the same message.

Broaching

Broaching CNC Machining

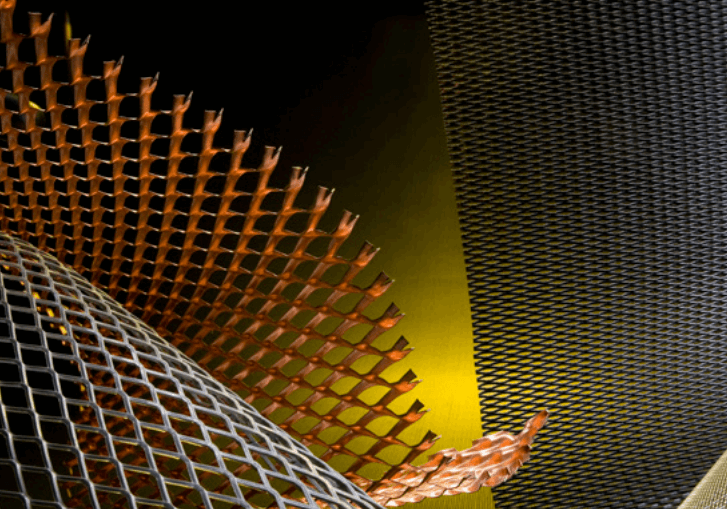

CNC Machining Expanded Metals

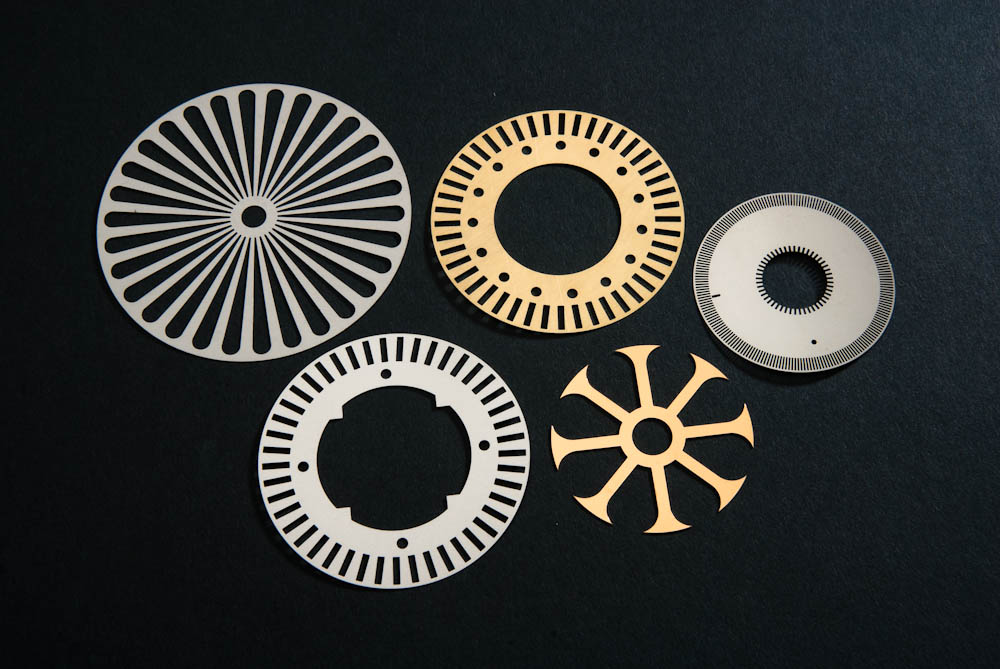

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

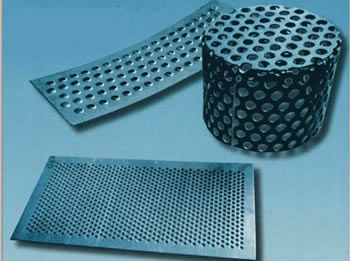

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

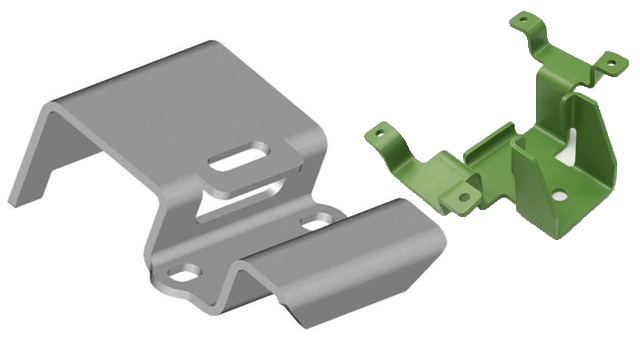

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services