Rotary broaching, also known as wobbling broaching, is a unique, quick, fantastic, and exact method of creating internal and exterior polygon forms on the end of a workpiece. The conventional broaching method entails inserting successively larger polygonal or other shapes into a hole until the desired form size is attained. By cutting the entire form, one corner at a time, rotary broaching can accomplish this in a single pass, frequently removing the need for a subsequent operation. This process works incredibly well on machines with horizontal or vertical spindles such as lathes, mills, etc. Read More…

Pioneer Broach Company is premier vendor of quality rotary broaching cutting tools. We specialize in custom spline, serration and hexalobular shaped rotary or wobble broaches, and also offer a complete line of standard hex and square rotary broach tools. Our new rotary broaching toolholder is designed for all modern CNC machines, mills and lathes.

Apex Broaching Systems is a worldwide supplier of standard broaching machines, special purpose broaching machines, fixturing, automation, and cutting tools. We have over 69 years of innovative engineering, skilled craftmanship, quality manufacturing, assembly, and customer satisfaction. All of our products are made here in the USA. Contact us today and tell us how we can meet your demands!

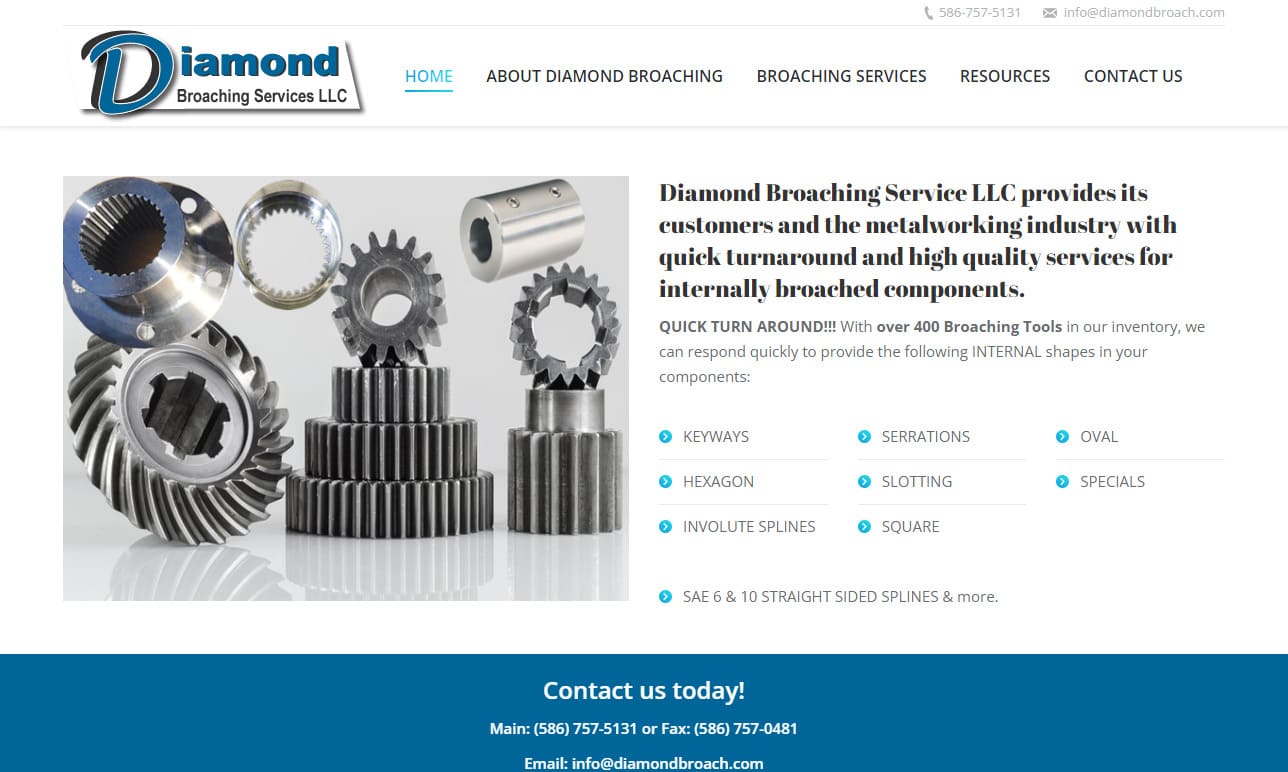

Diamond Broaching Service LLC showcases its value to its customers and the industry through quality customer service. The new team of Engineers and Machinists continue to provide the same high quality broaching services that our customers have depended on for over 70 years. With over 400 Broaching Tools in our inventory, we can respond quickly to provide the following shapes in just about all...

Since 1981, Universal Broaching has made a name as a dependable broaching job shop that offers quality products, impeccable service & competitive pricing for all broaching needs, no matter the size of the run. We offer horizontal internal broaching, vertical surface broaching, blind hole keyseating, broach sharpening, reconditioning & repair, and engineering & manufacturing of broaches & fixtures.

More Rotary Broaching Companies

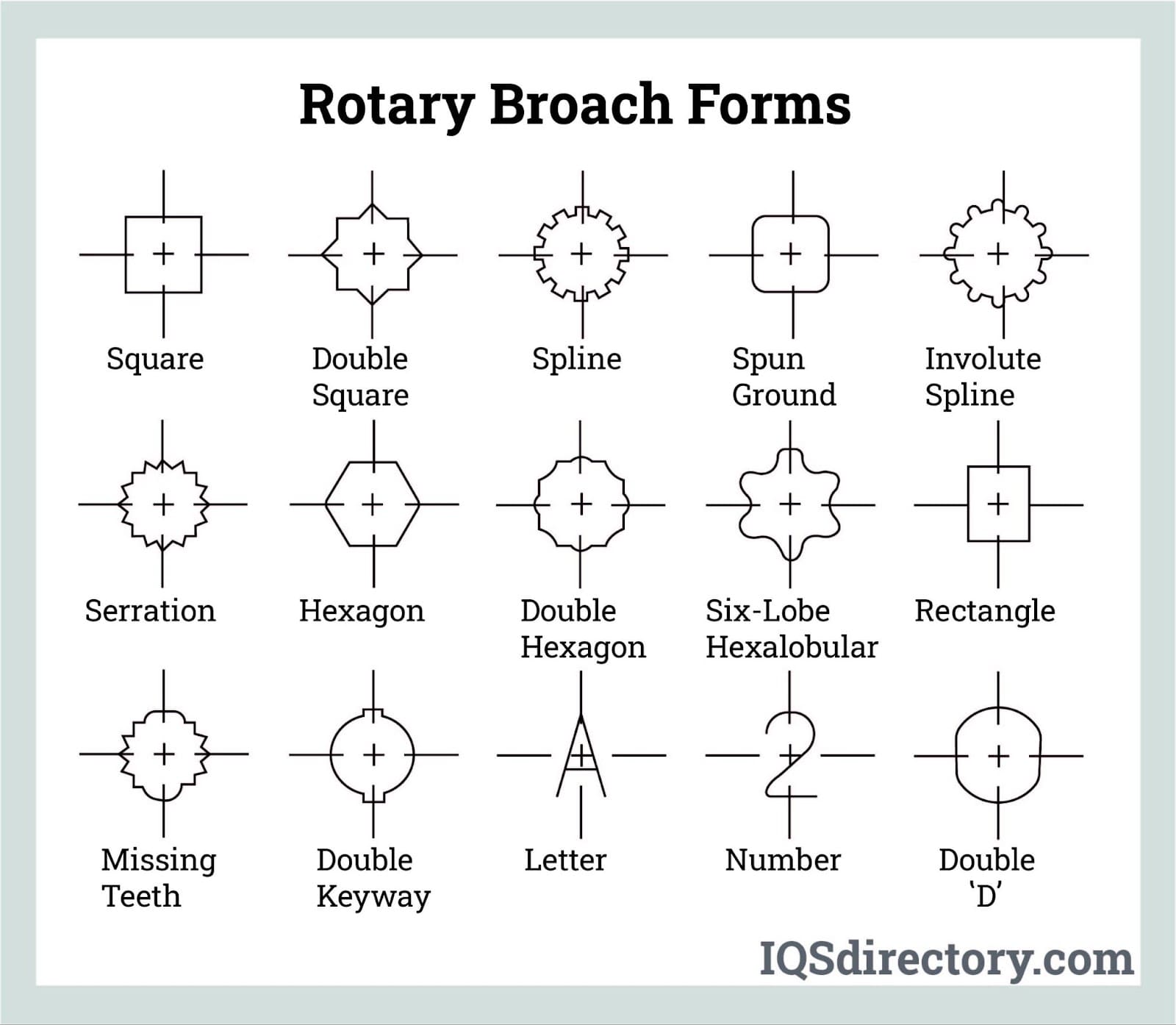

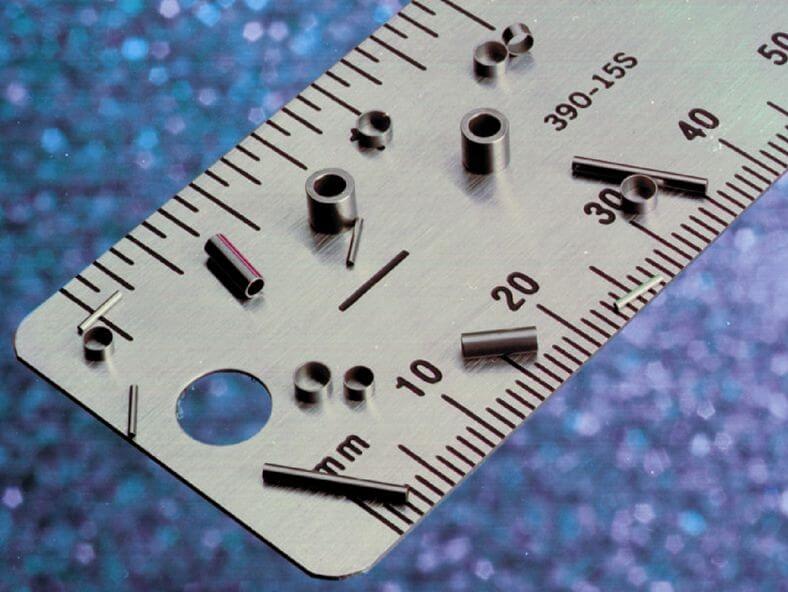

Internal polygon structures can be quickly and precisely created using the rotary broaching technique. The entire process can be finished in a matter of seconds, and forms can be produced with an accuracy of at least 0.0005′′. Rotary broaching has become more and more popular as a result of this cutting-edge engineering, particularly in the plumbing, automotive, aerospace and medical sectors. Rotary broaching is the best technique for inserting a polygon form into the end of a part without the requirement for a subsequent operation.

Requirements for the Rotary Broaching Process

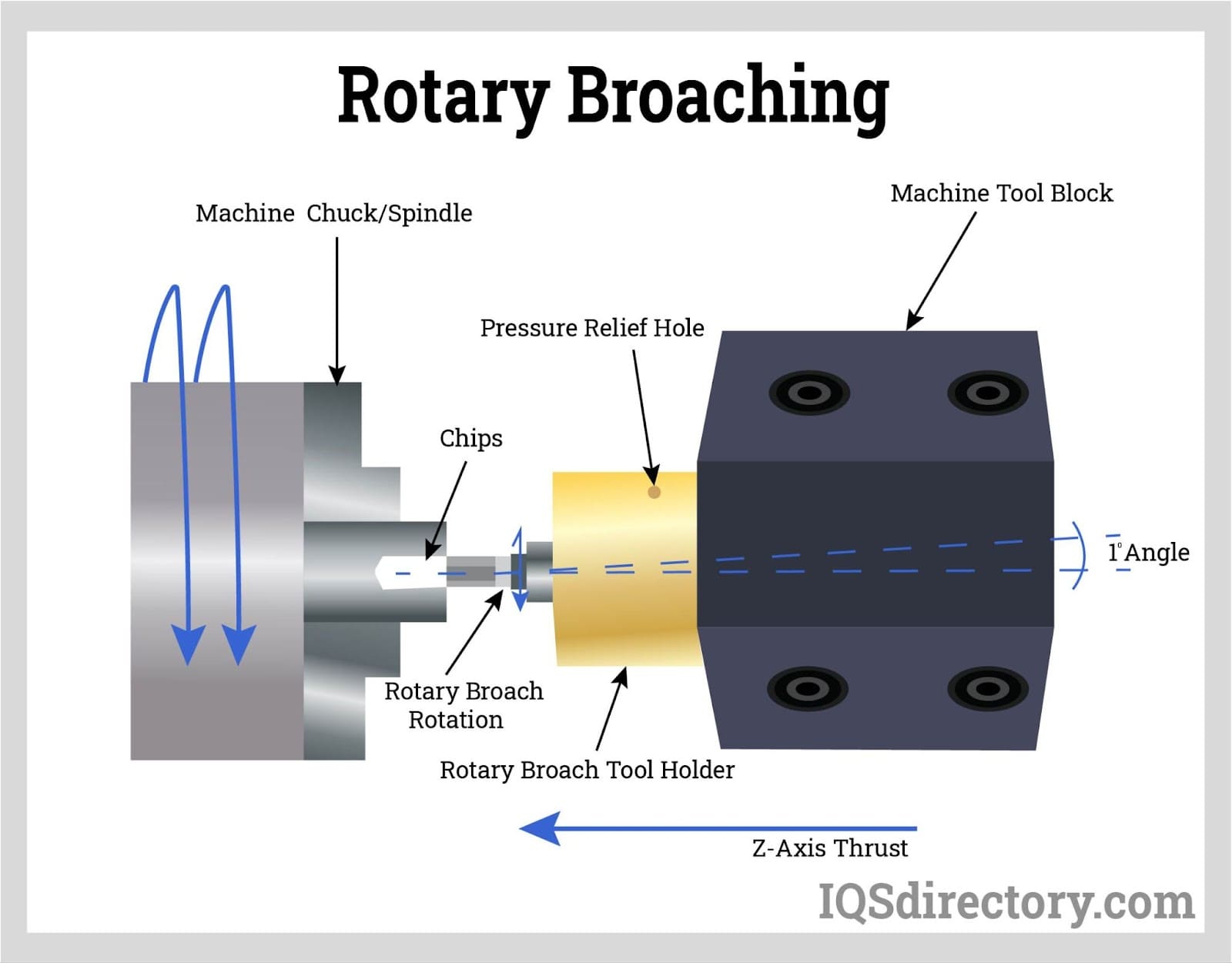

Any turning machine can essentially be converted into a rotary broaching machine. All that is required are the following two pieces of equipment.

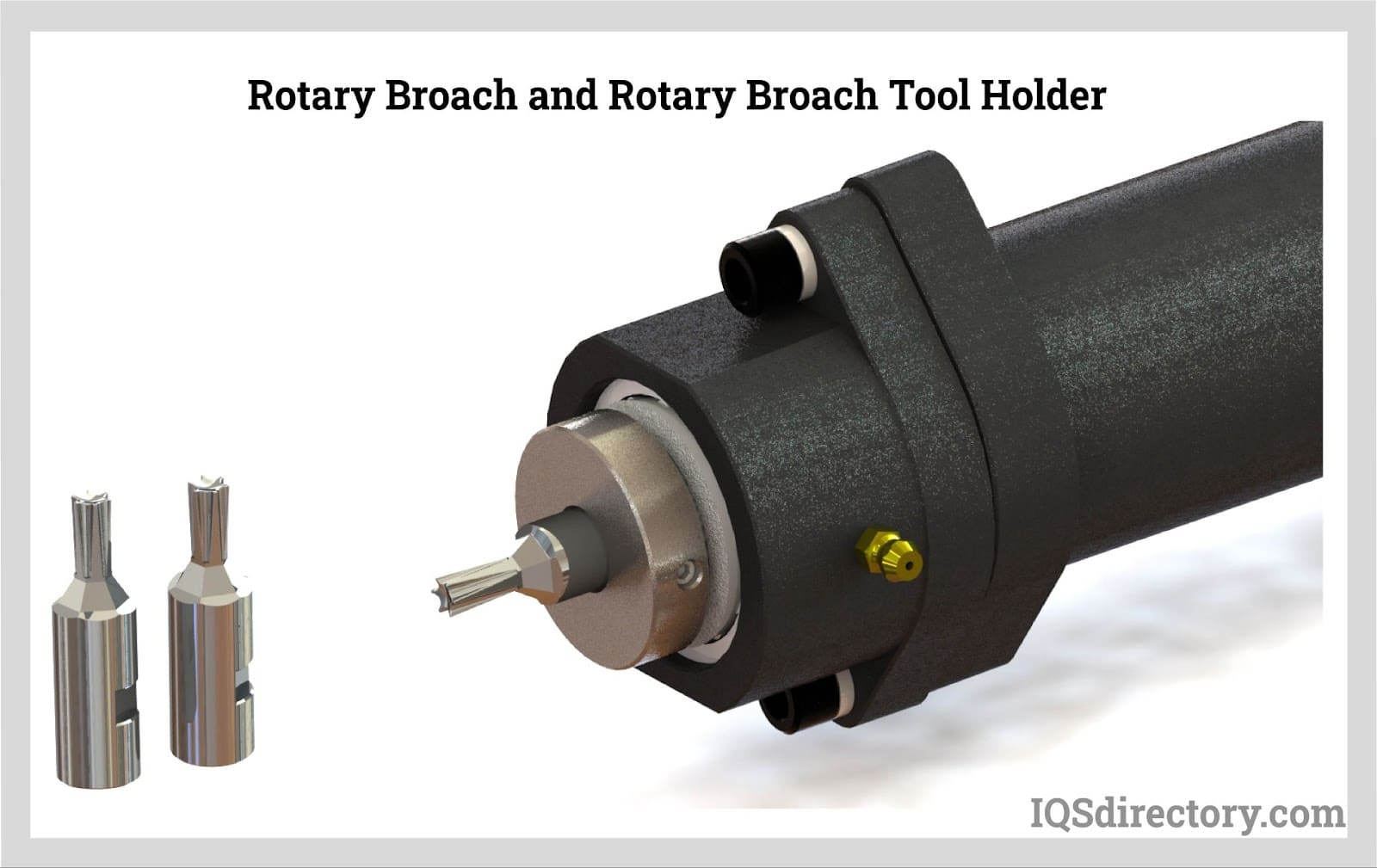

- Rotary broach: The rotary broach is the cutting tool used to cut a specific shape into, or remove a specific area from, a workpiece.

- Rotary broach tool holder: The rotary broach tool holder simply contains a mechanism that holds the broach in place and allows the spindle to rotate freely.

Machines That use Rotary Broaching

Here are some popular machines that are easily adapted to perform rotary broaching:

- CNC lathe machines

- Swiss lathe machines

- Milling machines

- Screw machines

Working Principle of Rotary Broaching

An internal live spindle within the rotary broach tool holder, holds an end-cutting broach tool. The internal live spindle and rotary broach of the rotary broach tool holder are positioned stationary on a lathe, screw, or other turning machine while the workpiece rotates around them. The rotary broach tool is driven by the workpiece, and as it cuts each corner of the form, its corners are constantly changing contact points with the workpiece, creating a wobbling-like effect.

In a milling machine, the rotary broach tool and the internal live spindle of the tool holder remain fixed while the body of the tool holder revolves with the machine spindle. Additionally, because the corners of the rotary broach tool are constantly changing their points of contact with the workpiece, this results in a wobbling-like motion. Up to 2 inches of aluminum, 1.5 inches of brass, and 1 inch of steel can be broached for form sizes. Numerous other materials and depths have been successfully rotary broached, therefore this should just be used as a point of reference.

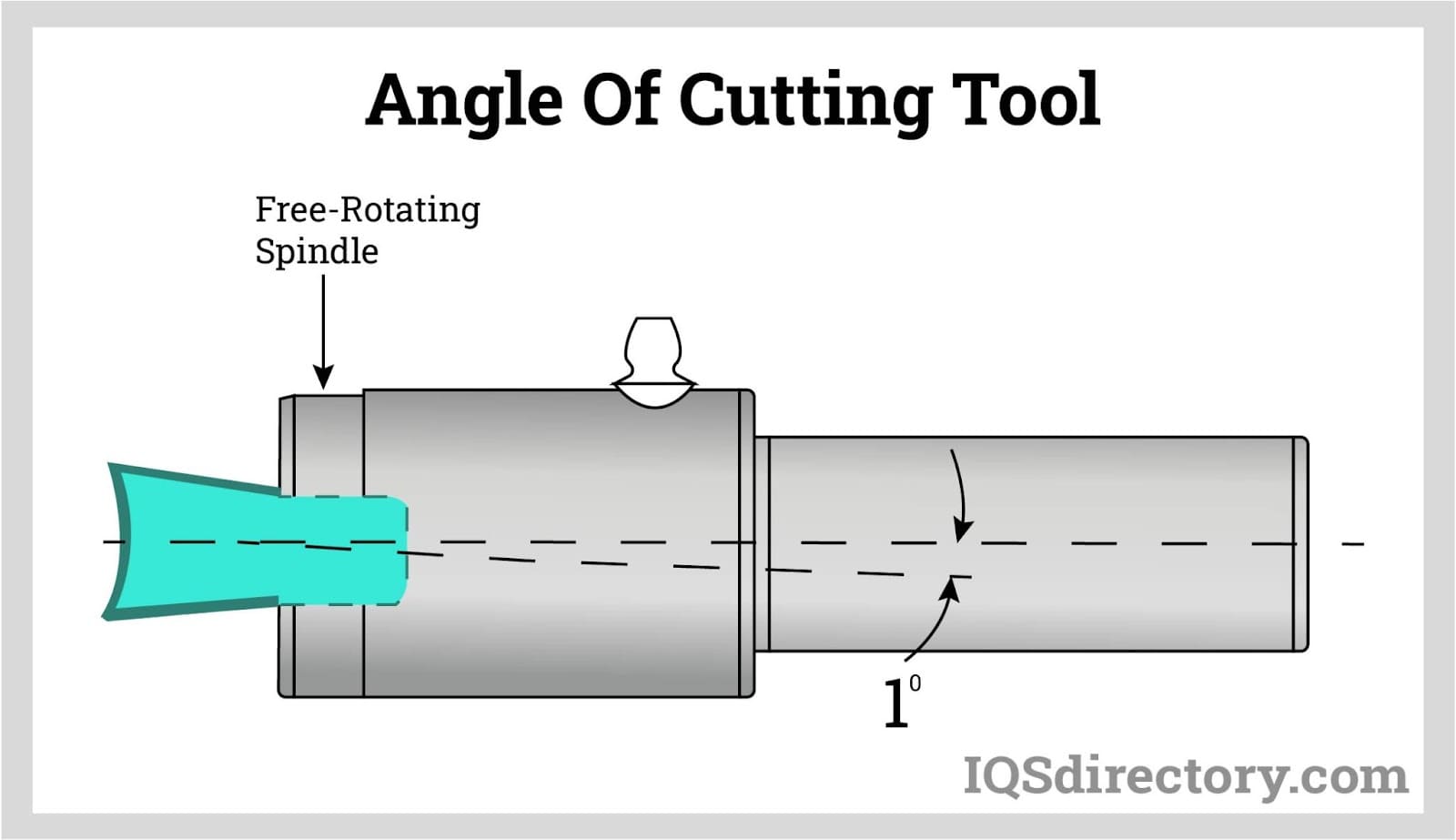

1° Angle

The secret to this technique's success is the cutting tool's 1° angle to the midline of the workpiece. As the rotary broach is fed into the part to the necessary depth, it shears into the workpiece with a chisel or scalloping effect. The broaching tool is held in place by a live spindle in the rotary broach tool holder, which allows the spindle to rotate freely inside the tool holder. In a lathe, the spindle is propelled by contact with the rotating workpiece. There is not much setup needed because the rotary broach tool holders do not require adjustments. These holders have characteristics like sealed bearings (which don't need routine maintenance) and a hole for pressure relief that lets air and fluid through.

Rotating Spindle

With rotary broaching, the broach is first inserted into the workpiece. Typically, a pilot hole is driven into the workpiece in order to properly introduce the broach in it. Then, the workpiece is rotated by the spindle. The broach holder then rotates causing the broach to wobble as it moves along the workpiece.

Cuts Each Corner Individually

Any turning machine can use the rotary broach tool. As it is fed into the workpiece, the spinning motion causes the broach to wobble from corner to corner and use all of the machine's power to cut just one corner at a time. As it is fed into the workpiece, the cutter travels in a helical pattern.

Precision Form

Rotary broaching yields extremely exact forms. Despite being held at a one-degree inclination, the incline is so modest that the finished product's dimensional correctness matches the cutting tool's dimensions. Normally, rotary broaches are produced with a +0/-.0005" tolerance.

Advice Regarding Rotary Broaching

In order to achieve the best results, it is suggested that the ideal forming depth for rotary broaching is up to 1.5 times the distance across flats, or the diameter of the inscribed circular profile. Once more, this is merely a point of reference. Deeper depths can be reached depending on the application.

Benefits of Rotary Broaching

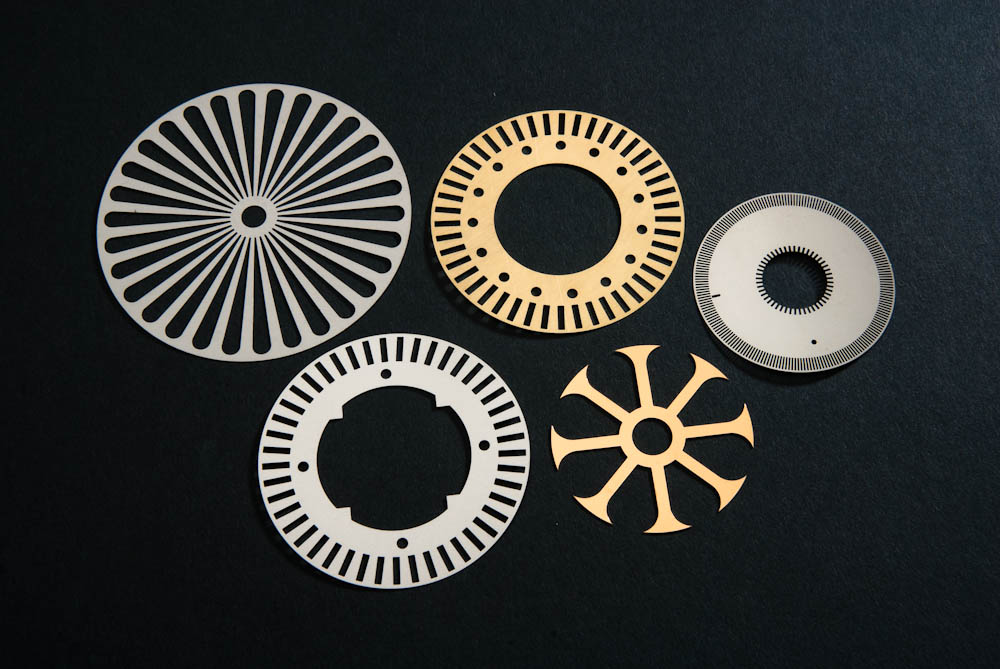

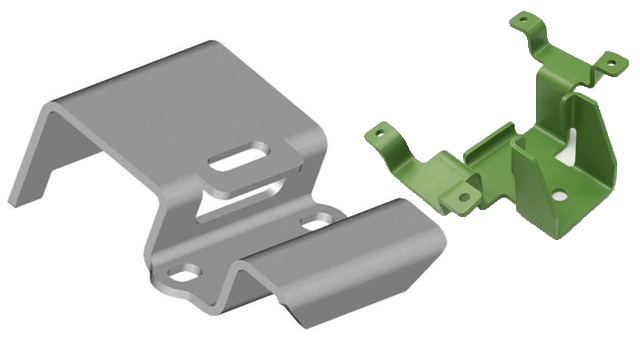

Although squares and hexagons are the most common shapes produced, rotary broaching creates a variety of items with intricate forms (see below) or workpieces with exquisite designs at their ends with a great finished quality. It is typically employed to produce the mechanical parts required throughout the manufacturing process and is used elsewhere in limited applications. It can be utilized on a variety of common materials such as plastic, cast iron, aluminum, and stainless steel; it can be used with other materials as well. Basically, any turning machine can be set up for rotary broaching after an inexpensive tooling setup. After this initial investment and setup, further maintenance costs are low, especially in relation to how quickly and inexpensively parts may be completed.

Choosing the Proper Rotary Broaching Supplier

To make sure you have the most beneficial outcome when purchasing Rotary Broaching from a Rotary Broaching Company, it is important to compare at least 4 or 5 Companies using our list of Rotary Broaching suppliers. Each Rotary Broaching Company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Rotary Broaching company website using our proprietary website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple Rotary Broaching businesses with the same quote.

Broaching

Broaching CNC Machining

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

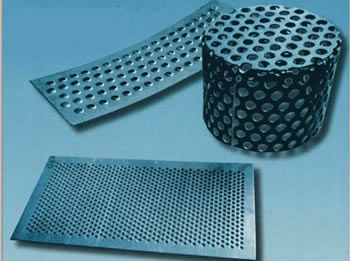

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services