A keyway is a slot or channel in a machine part that is designed to accommodate a key, which is a small metal insert used for torque transmission between two rotating components. Keyway broaching is a machining process that involves removing material from a workpiece to create a keyway slot using a broaching tool. The broaching tool is a long, narrow cutting tool that contains a series of teeth or cutting edges that gradually increase in size from the entrance end to the exit end. Read More…

Pioneer Broach Company is premier vendor of quality rotary broaching cutting tools. We specialize in custom spline, serration and hexalobular shaped rotary or wobble broaches, and also offer a complete line of standard hex and square rotary broach tools. Our new rotary broaching toolholder is designed for all modern CNC machines, mills and lathes.

Apex Broaching Systems is a worldwide supplier of standard broaching machines, special purpose broaching machines, fixturing, automation, and cutting tools. We have over 69 years of innovative engineering, skilled craftmanship, quality manufacturing, assembly, and customer satisfaction. All of our products are made here in the USA. Contact us today and tell us how we can meet your demands!

Diamond Broaching Service LLC showcases its value to its customers and the industry through quality customer service. The new team of Engineers and Machinists continue to provide the same high quality broaching services that our customers have depended on for over 70 years. With over 400 Broaching Tools in our inventory, we can respond quickly to provide the following shapes in just about all...

Since 1981, Universal Broaching has made a name as a dependable broaching job shop that offers quality products, impeccable service & competitive pricing for all broaching needs, no matter the size of the run. We offer horizontal internal broaching, vertical surface broaching, blind hole keyseating, broach sharpening, reconditioning & repair, and engineering & manufacturing of broaches & fixtures.

More Keyway Broaching Companies

How Keyway Broaching Is Performed

The process of keyway broaching is typically broken down into several steps:

Setup

The workpiece is secured in a fixture or holding device, which allows for precise positioning and alignment of the part during the broaching process.

Preliminary Machining

If necessary, the workpiece is pre-machined to remove excess material or to prepare the surface for broaching.

Broaching

The broaching tool is then inserted into the workpiece and is gradually pushed or pulled through the material using a broaching machine. As the broaching tool moves through the workpiece, it removes material to create the keyway slot.

Finishing

Once the broaching process is complete, the workpiece is inspected for dimensional accuracy and surface finish. If necessary, additional finishing operations such as deburring or polishing may be performed.

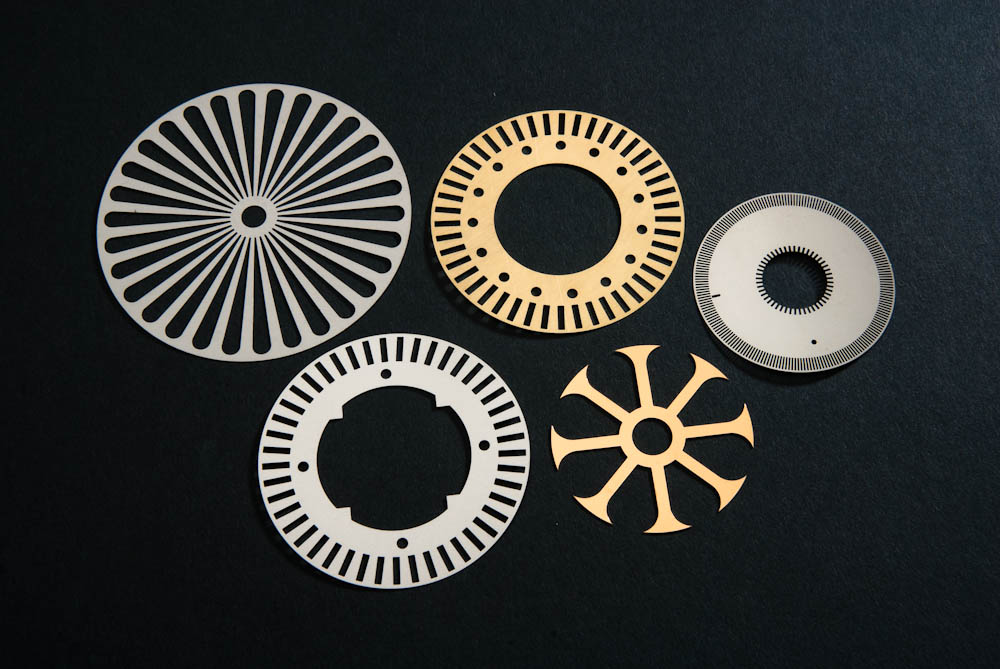

Types of Keyway Broaching

Internal broaching, external broaching, and surface broaching are all variations of keyway broaching. Here's a brief overview of each type and their specific applications:

Internal Broaching

Internal broaching is used to create keyways inside of a cylindrical bore or hole. The broaching tool is designed with teeth or cutting edges along its length, allowing it to gradually remove material and create the keyway. Internal broaching is commonly used in the production of gears, pulleys, and other components that require precise keyway slots for connecting to other parts. This type of broaching is particularly useful for creating internal keyways in parts that are difficult or impossible to machine with other methods.

External Broaching

External broaching is used to create keyways on the outside surface of a workpiece. The broaching tool is similar to that used for internal broaching, but is designed to work on the outside of the part. External broaching is commonly used in the production of shafts, couplings, and other components that require keyways for connecting to other parts. This type of broaching is particularly useful for creating precise keyways on the outer surface of parts that are difficult or impossible to machine with other methods.

Surface Broaching

Surface broaching is used to create keyways on flat surfaces of a workpiece. The broaching tool is designed with teeth or cutting edges that gradually remove material to create the keyway. Surface broaching is commonly used in the production of machine parts, such as tool holders, that require keyways for holding cutting tools or other components. This type of broaching is particularly useful for creating precise keyways on flat surfaces that are difficult or impossible to machine with other methods.

Keyway Broaching: In-House or through a Service?

Keyway broaching can be done both in-house and as a service, depending on the needs and capabilities of the manufacturer. Some manufacturers may have their own keyway broaching machines and skilled operators, allowing them to perform the process in-house. This can provide greater control over the production process, as well as potentially lower costs and faster turnaround times. However, other manufacturers may not have the equipment or expertise to perform keyway broaching in-house. In this case, they may outsource the process to a specialized keyway broaching service provider. These providers may have a range of broaching machines and experienced operators, allowing them to produce high-quality keyways to exact specifications. Ultimately, the decision to perform keyway broaching in-house or outsource it to a service provider will depend on factors such as the volume of parts being produced, the required level of precision, and the availability of resources and expertise within the manufacturing organization.

Considerations Regarding Keyway Broaching

While keyway broaching can be a useful and effective machining process, there are also some things to consider. Keyway broaching can have rapid tool wear, difficulty in machining hard or brittle materials, significant setup time for complex keyway shapes, and relatively high cost compared to other machining methods. Furthermore, once a keyway has been broached into a part, it cannot be easily changed or modified. This can limit the flexibility of the part for future use or modifications.

Benefits of Keyway Broaching

Despite these considerations, keyway broaching can offer several benefits, including:

Precision

Keyway broaching allows for precise control over the dimensions of the keyway, resulting in a high degree of accuracy and consistency in the finished part.

Efficiency

Keyway broaching can be a relatively fast and efficient process, particularly for producing high volumes of parts with identical or similar keyway shapes and sizes.

Durability

Keyway broaching can create keyways with precise shapes and sizes that can provide a strong and durable connection between two parts, helping to ensure the longevity and reliability of the finished product.

Versatility

Keyway broaching can be used to create a wide range of keyway shapes and sizes, making it a versatile process that can be applied to a variety of parts and applications.

Quality

Keyway broaching can produce keyways with a smooth surface finish and tight tolerances, resulting in a high-quality finished product.

Compatibility

Keyway broaching can create keyways that are compatible with a variety of different types of keys, allowing for greater flexibility and adaptability in the design of the finished product.

Applications of Keyway Broaching

Keyway broaching is used in a variety of applications, including:

Automotive Industry

Keyway broaching is commonly used in the production of automotive parts such as gears, shafts, and couplings, which require precise keyways for connecting to other parts.

Aerospace Industry

Keyway broaching is used in the production of aircraft engine components such as gearboxes, turbine blades, and rotors, which require precise keyways for proper assembly and operation.

Industrial Machinery

Keyway broaching is used in the production of industrial machinery components such as hydraulic and pneumatic cylinders, pumps, and valves, which require precise keyways for proper function.

Construction Equipment

Keyway broaching is used in the production of construction equipment components such as pulleys, gears, and sprockets, which require precise keyways for transmitting power and torque.

Marine Industry

Keyway broaching is used in the production of marine propulsion system components such as propellers, shafts, and couplings, which require precise keyways for transmitting power and torque.

Tooling

Keyway broaching is used in the production of tooling components such as cutting tool holders, which require precise keyways for holding cutting tools and other components.

Choosing the Right Keyway Broaching Option

To ensure you have the most beneficial outcome when choosing keyway broaching options, it is important to compare several keyway broaching equipment services and equipment manufacturers using our directory of keyway broaching services and equipment manufacturers. Each keyway broaching-related company has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with them for more information or to request a quote for service or equipment. Review each keyway broaching-related company using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple keyway broaching services or keyway broaching equipment manufacturers with the same form.

Broaching

Broaching CNC Machining

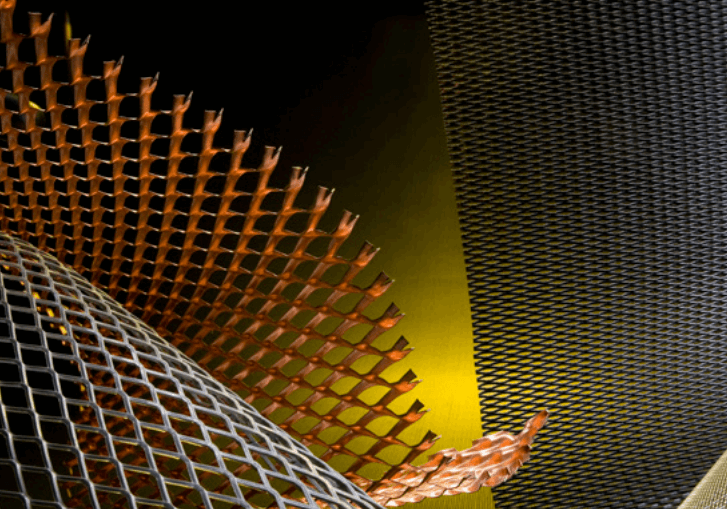

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

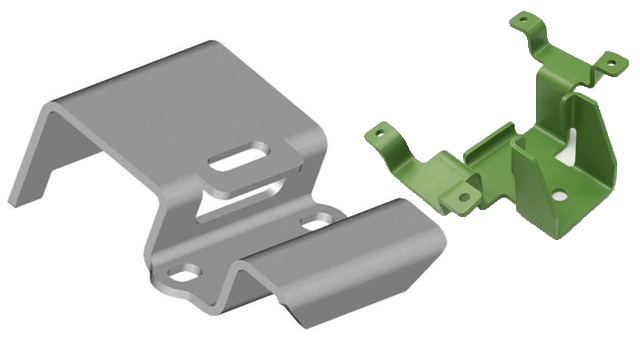

Metal Etching Metal Fabrication

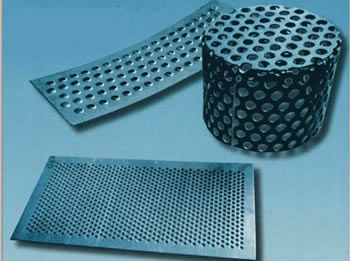

Metal Fabrication Perforated Metals

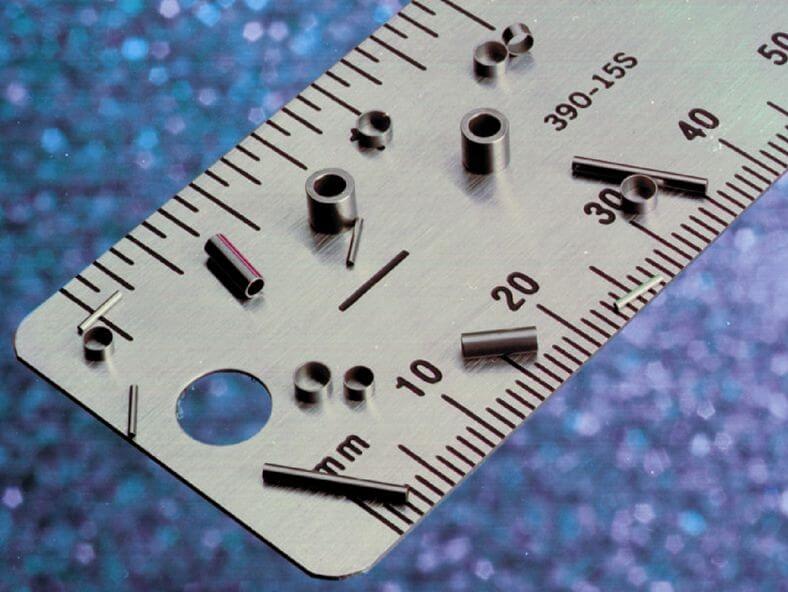

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services