The biggest draw of the broaching process is the custom broach fabrication process, in which your manufacturing can fabricate a broach tool with your exact specifications and application in mind in order to create the best possible final product for you. In order to find the best possible manufacturer you will need to assess your application and determine your needs and wants, from there you will consult manufacturers with broaching capabilities until you find a company that either specializes in your application or has the years of experience and knowledge to offer you custom broach fabrication. Read More…

Pioneer Broach Company is premier vendor of quality rotary broaching cutting tools. We specialize in custom spline, serration and hexalobular shaped rotary or wobble broaches, and also offer a complete line of standard hex and square rotary broach tools. Our new rotary broaching toolholder is designed for all modern CNC machines, mills and lathes.

Apex Broaching Systems is a worldwide supplier of standard broaching machines, special purpose broaching machines, fixturing, automation, and cutting tools. We have over 69 years of innovative engineering, skilled craftmanship, quality manufacturing, assembly, and customer satisfaction. All of our products are made here in the USA. Contact us today and tell us how we can meet your demands!

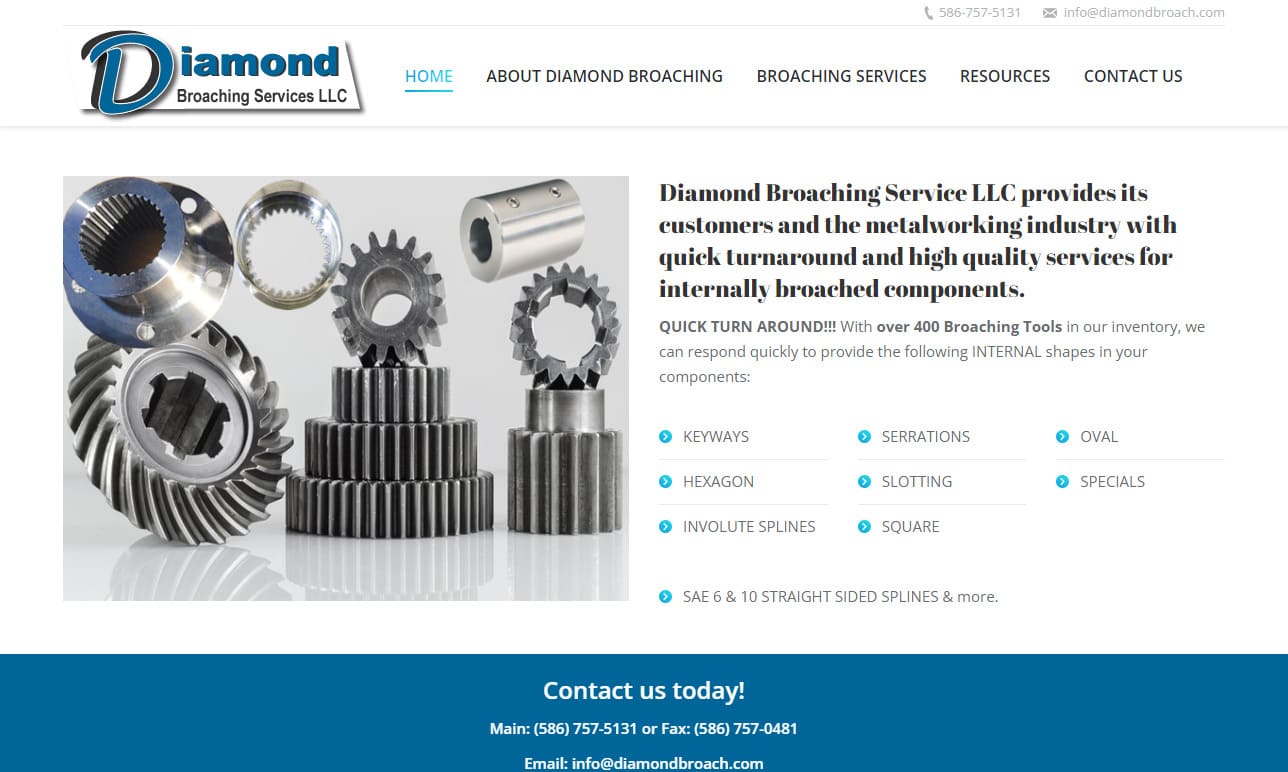

Diamond Broaching Service LLC showcases its value to its customers and the industry through quality customer service. The new team of Engineers and Machinists continue to provide the same high quality broaching services that our customers have depended on for over 70 years. With over 400 Broaching Tools in our inventory, we can respond quickly to provide the following shapes in just about all...

Since 1981, Universal Broaching has made a name as a dependable broaching job shop that offers quality products, impeccable service & competitive pricing for all broaching needs, no matter the size of the run. We offer horizontal internal broaching, vertical surface broaching, blind hole keyseating, broach sharpening, reconditioning & repair, and engineering & manufacturing of broaches & fixtures.

More Broach Fabrication Companies

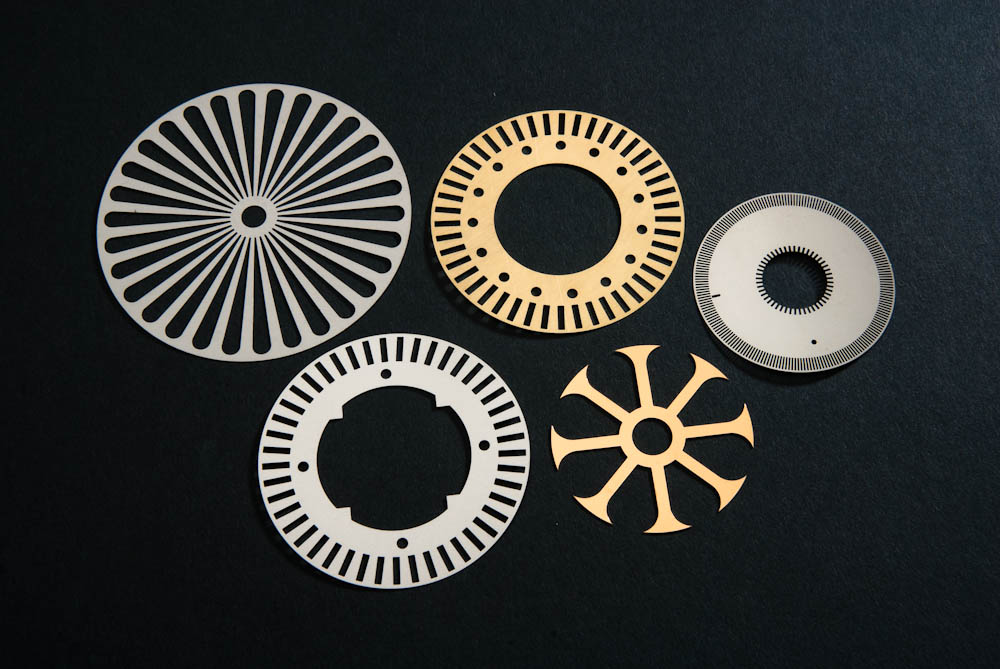

There are a number of different types of broaches that can be made; these are typically categorized by their use, purpose, motion, construction, or simply by their function. The overall broaching process can be a bit costly, so it is more commonly used within large production runs or runs where a high quantity of parts is needed in order to justify the custom of the initial broach fabrication.

In order to determine which type of broach you will need, you must look at your application and either provide a blue print to the manufacturer for them to follow or be very precise in how you outline your requirements. Broaches can be broken up into two main categories, surface broaches and internal broaches.

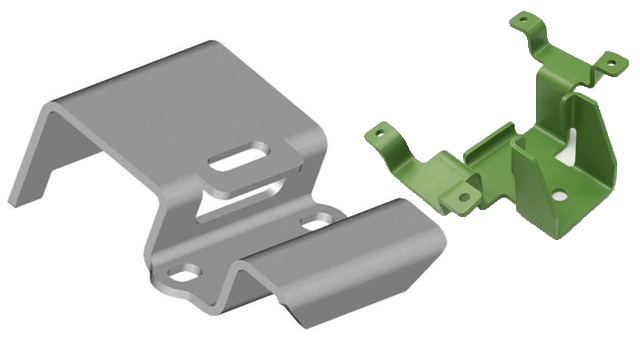

Surface broaches have a variety of subcategories from the slab broach which cuts flat surfaces to the straddle broach which is basically two slab broaches that cut a parallel surface.

Internal broaches also have a variety of subcategories such as modular broaches which are used for larger internal broaching applications to cut-and-recut broaches which are typically used to cut thin-walled objects.

Whatever your application may be, working with the right manufacturer is the best way to ensure that you receive the highest quality final product.

Remember that the highest cost comes from the actual broach fabrication process so verify that your production is a large enough quantity to justify the broaching and broach fabrication process.

Broaching

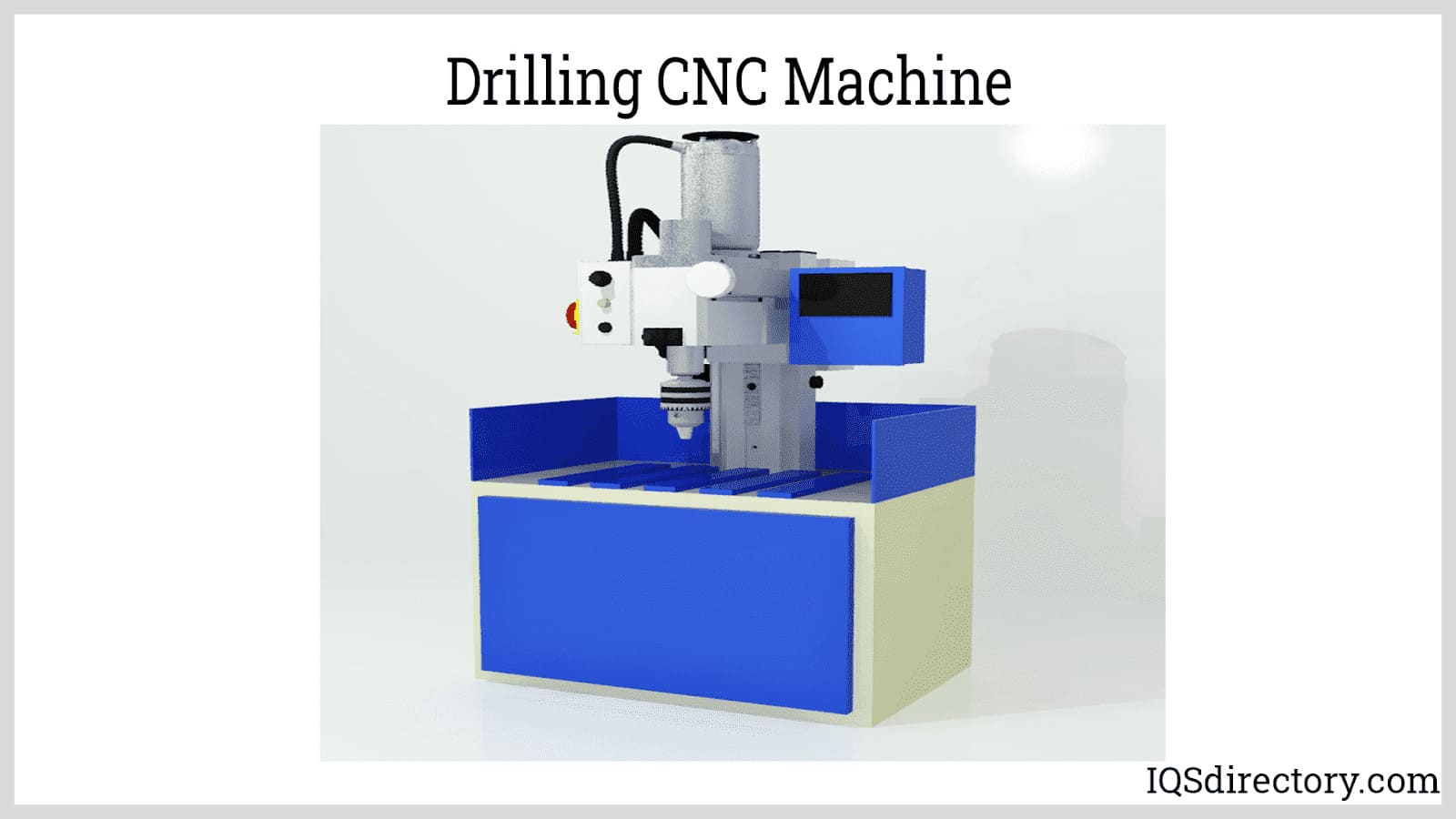

Broaching CNC Machining

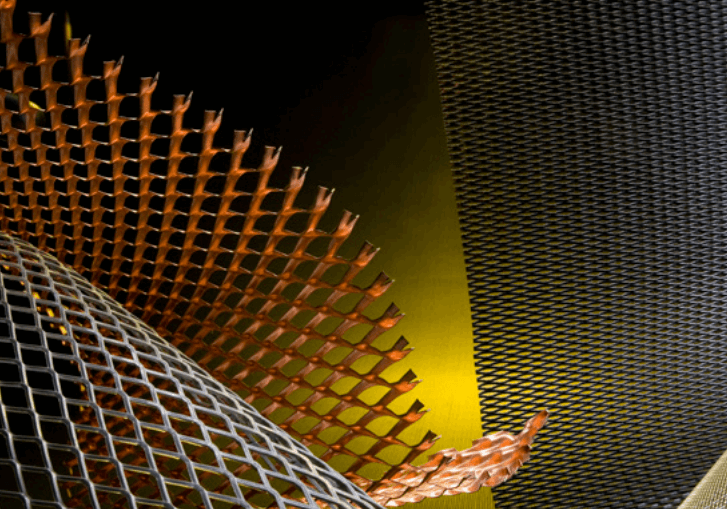

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

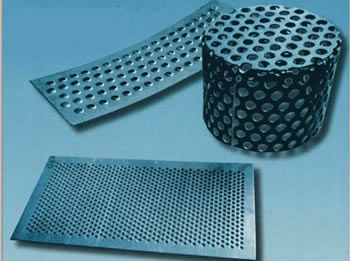

Metal Fabrication Perforated Metals

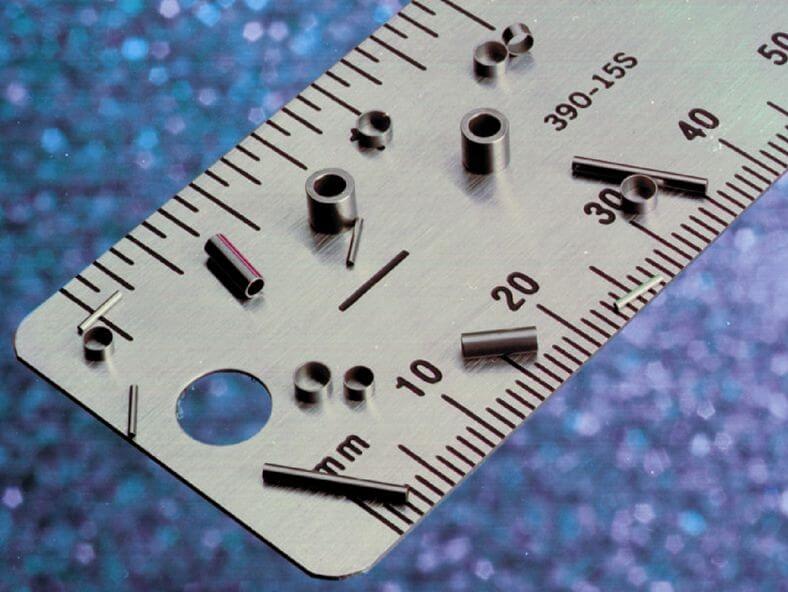

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services