Unlike other broaching operations, blind hole broaching does not allow the tool to pass completely through the metal part. Instead, it produces an indent or slot in the metal. Every aspect of this type of broaching, especially the tooling design and execution, are very difficult and are only done by skilled, experienced broachers. Read More…

Pioneer Broach Company is premier vendor of quality rotary broaching cutting tools. We specialize in custom spline, serration and hexalobular shaped rotary or wobble broaches, and also offer a complete line of standard hex and square rotary broach tools. Our new rotary broaching toolholder is designed for all modern CNC machines, mills and lathes.

Apex Broaching Systems is a worldwide supplier of standard broaching machines, special purpose broaching machines, fixturing, automation, and cutting tools. We have over 69 years of innovative engineering, skilled craftmanship, quality manufacturing, assembly, and customer satisfaction. All of our products are made here in the USA. Contact us today and tell us how we can meet your demands!

Diamond Broaching Service LLC showcases its value to its customers and the industry through quality customer service. The new team of Engineers and Machinists continue to provide the same high quality broaching services that our customers have depended on for over 70 years. With over 400 Broaching Tools in our inventory, we can respond quickly to provide the following shapes in just about all...

Since 1981, Universal Broaching has made a name as a dependable broaching job shop that offers quality products, impeccable service & competitive pricing for all broaching needs, no matter the size of the run. We offer horizontal internal broaching, vertical surface broaching, blind hole keyseating, broach sharpening, reconditioning & repair, and engineering & manufacturing of broaches & fixtures.

More Blind Broaching Companies

Although broaching styles that pierce from one side to the other, such as internal broaching require careful machining as well, it is not quite as difficult as a set-up that must only go part way through a surface.

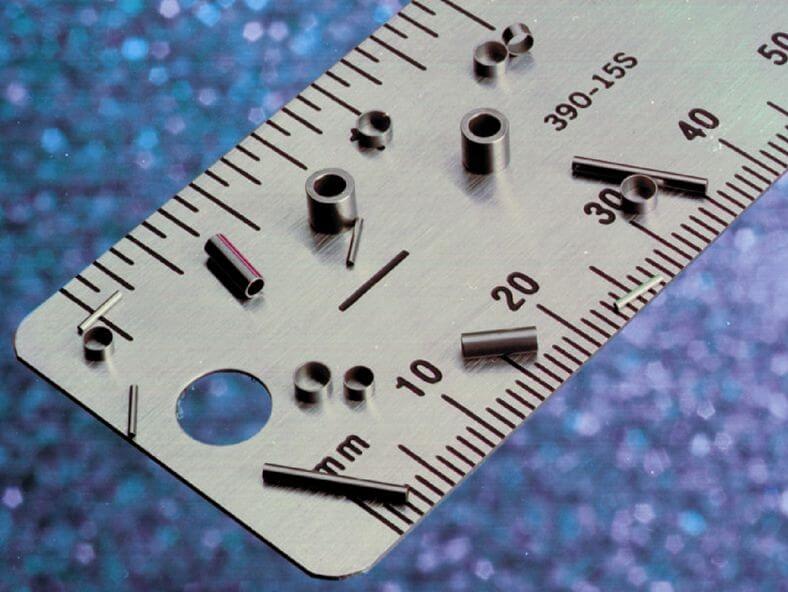

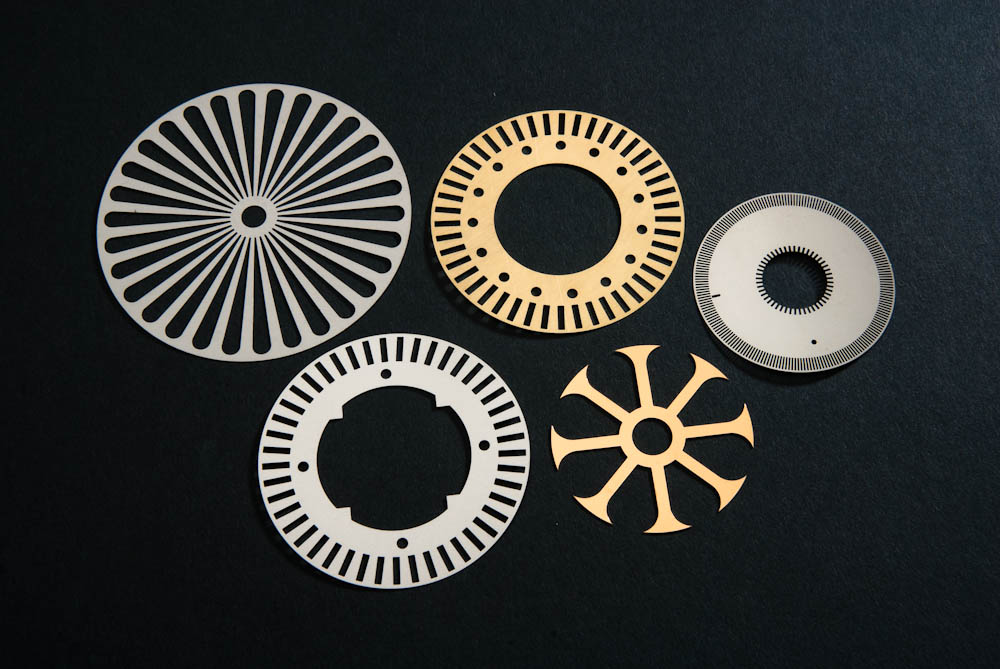

Blind broaching is reserved for cutting slots, holes and imprints that are round, square, hexagonal or splines in hardware and parts for the aerospace and construction industries. A common example of a blind hole broached product is the internal hexagon on headless setscrews.

Applications for a broached blind hole are rare, but it is the only process able to produce holes with the necessary shapes and dimensions for some metal parts. It's also an economical and efficient means of internal spline production. Broaching blind holes is cost effective, highly repeatable and produces no variance among the products.

The blind holes produced by broaching machinery have a good surface finish when the part's material is hardened, smooth edges without burrs or cracks. The broaching machine is either hydraulically or electromechanically driven and, depending on the volume of work-pieces, is manually or automatically loaded and unloaded.

Blind broaching is either straight, meaning the tool containing the teeth is long and thin and moves linearly, or helical, which means the tool is rounded and moves in a circular motion; helical broaching is the most common. It uses a series of circular indexing tables that rotate under or over the work-piece.

The machinery pushes the work-piece up over the tool, where a shape punches down, withdraws and then turns to the next shape, which is bigger than the last. The next tool is positioned over the small punch, and is made bigger.

Some broaching machinery has dozens of successively larger tools that slowly create a larger blind hole. Each tool must be withdrawn backward over the broached surface, unlike most other broaching processes, which cut straight through the work-piece.

Broaching

Broaching CNC Machining

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

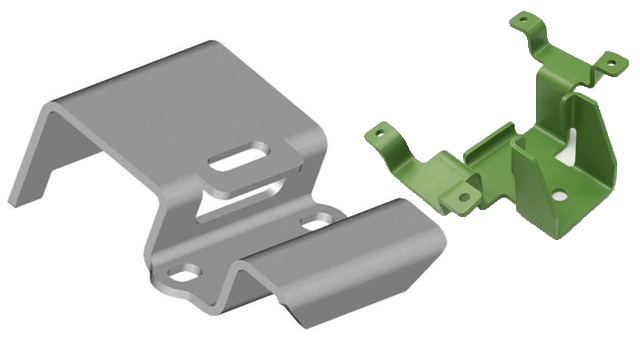

Metal Fabrication Perforated Metals

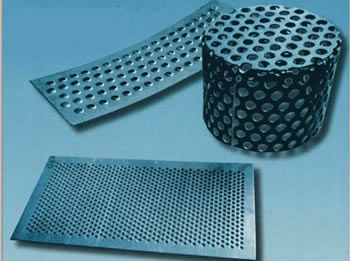

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services