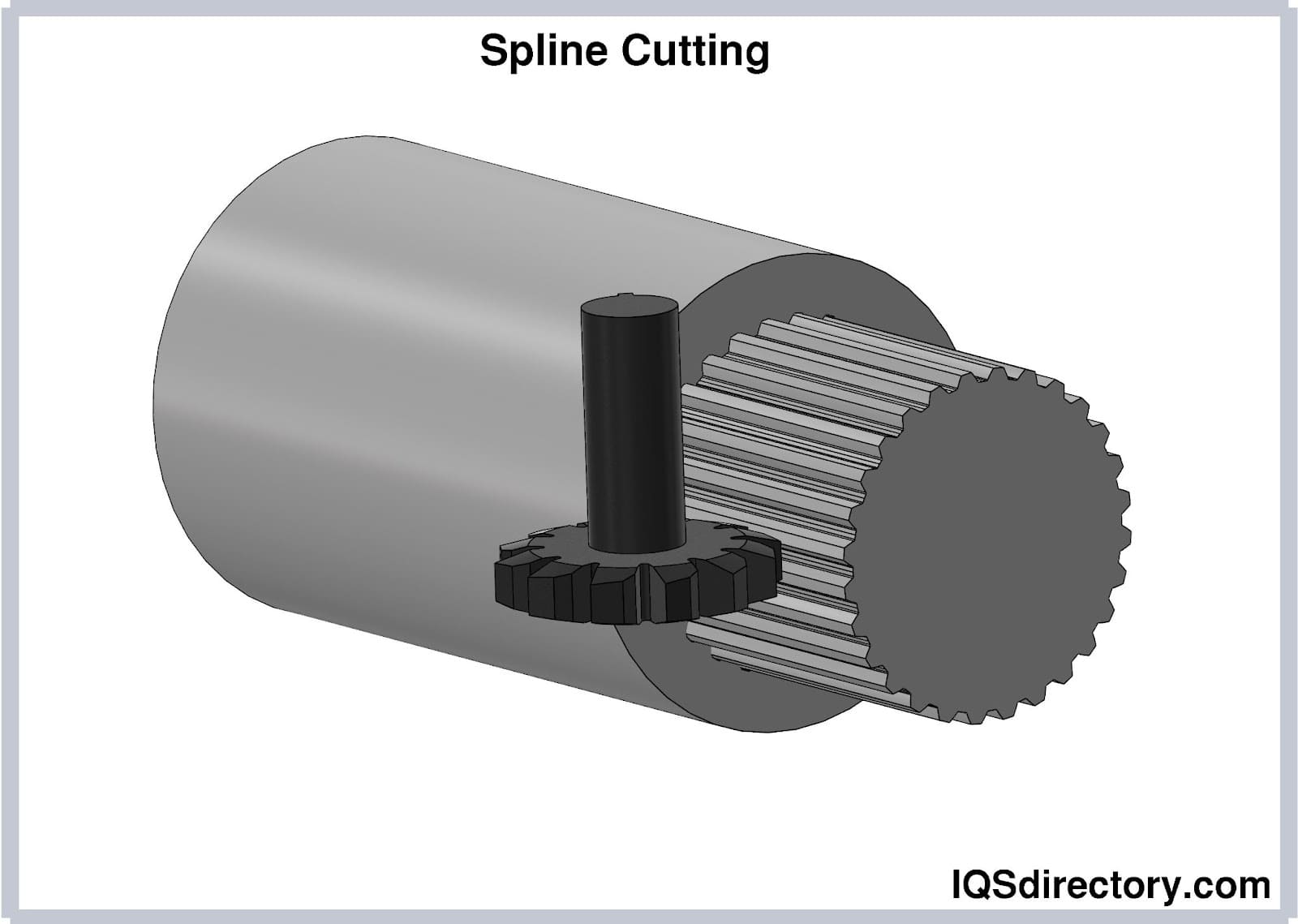

Spline cutting is the process of machining internal or external splines (ridges or teeth) onto shafts, gears, and other mechanical power transmission components. The ridges or teeth created are intended to mesh with grooves in a mating piece in order to transfer power from one to the other. Read More…

Pioneer Broach Company is premier vendor of quality rotary broaching cutting tools. We specialize in custom spline, serration and hexalobular shaped rotary or wobble broaches, and also offer a complete line of standard hex and square rotary broach tools. Our new rotary broaching toolholder is designed for all modern CNC machines, mills and lathes.

Apex Broaching Systems is a worldwide supplier of standard broaching machines, special purpose broaching machines, fixturing, automation, and cutting tools. We have over 69 years of innovative engineering, skilled craftmanship, quality manufacturing, assembly, and customer satisfaction. All of our products are made here in the USA. Contact us today and tell us how we can meet your demands!

Diamond Broaching Service LLC showcases its value to its customers and the industry through quality customer service. The new team of Engineers and Machinists continue to provide the same high quality broaching services that our customers have depended on for over 70 years. With over 400 Broaching Tools in our inventory, we can respond quickly to provide the following shapes in just about all...

Since 1981, Universal Broaching has made a name as a dependable broaching job shop that offers quality products, impeccable service & competitive pricing for all broaching needs, no matter the size of the run. We offer horizontal internal broaching, vertical surface broaching, blind hole keyseating, broach sharpening, reconditioning & repair, and engineering & manufacturing of broaches & fixtures.

More Spline Cutting Companies

What is a Spline?

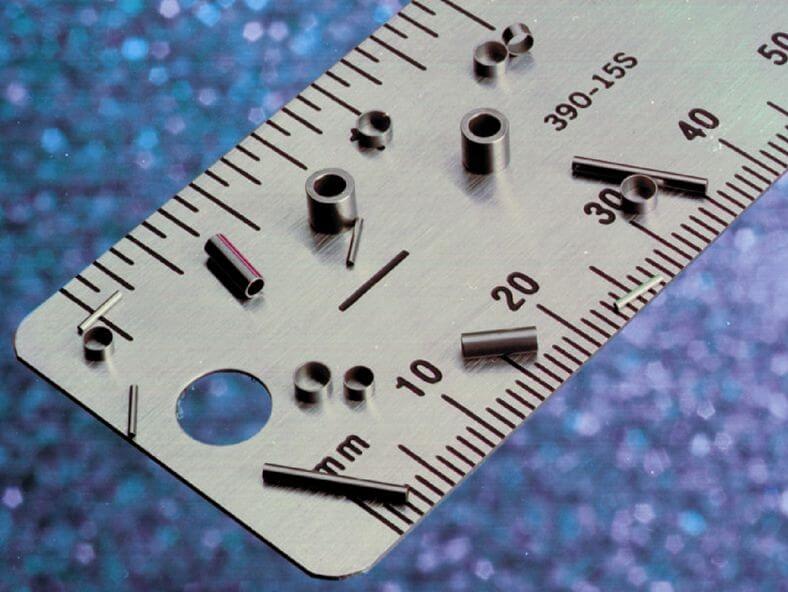

A spline is a shaft with a row of evenly spaced teeth that can be slotted into a matching component to transmit torque or act as an anti-rotational device. Splines are typically composed of stainless steel, carbon steel, alloy steel, or an aluminum alloy. Depending on the function, splines can be created for internal or exterior pieces and come in a range of tooth forms. Additionally, rotary devices such as gears can be mounted on the spline to perform a variety of tasks.

Any mechanism that converts rotary motion from an input to an output almost always makes use of a spline. Splines use a mechanical connection, such as a splined shaft, to transmit the rotating motion of an input to an output. The circumference of a splined shaft (typically) includes evenly spaced teeth that are frequently parallel to the shaft's axis of rotation. These teeth may have straight sides, involute form, or angle forms (serrations).

An internal spline with slots, or spaces, produced in the reverse of the shaft's teeth mates with an externally-splined shaft. The internally splined item, such as a gear or other rotating device, receives the rotation of the splined shaft. This rotation's transfer has a ratio of 1:1. Drive shafts and other spinning devices frequently contain splines. The rotating machinery that we encounter on a daily basis contains them.

Spline Cutting Techniques

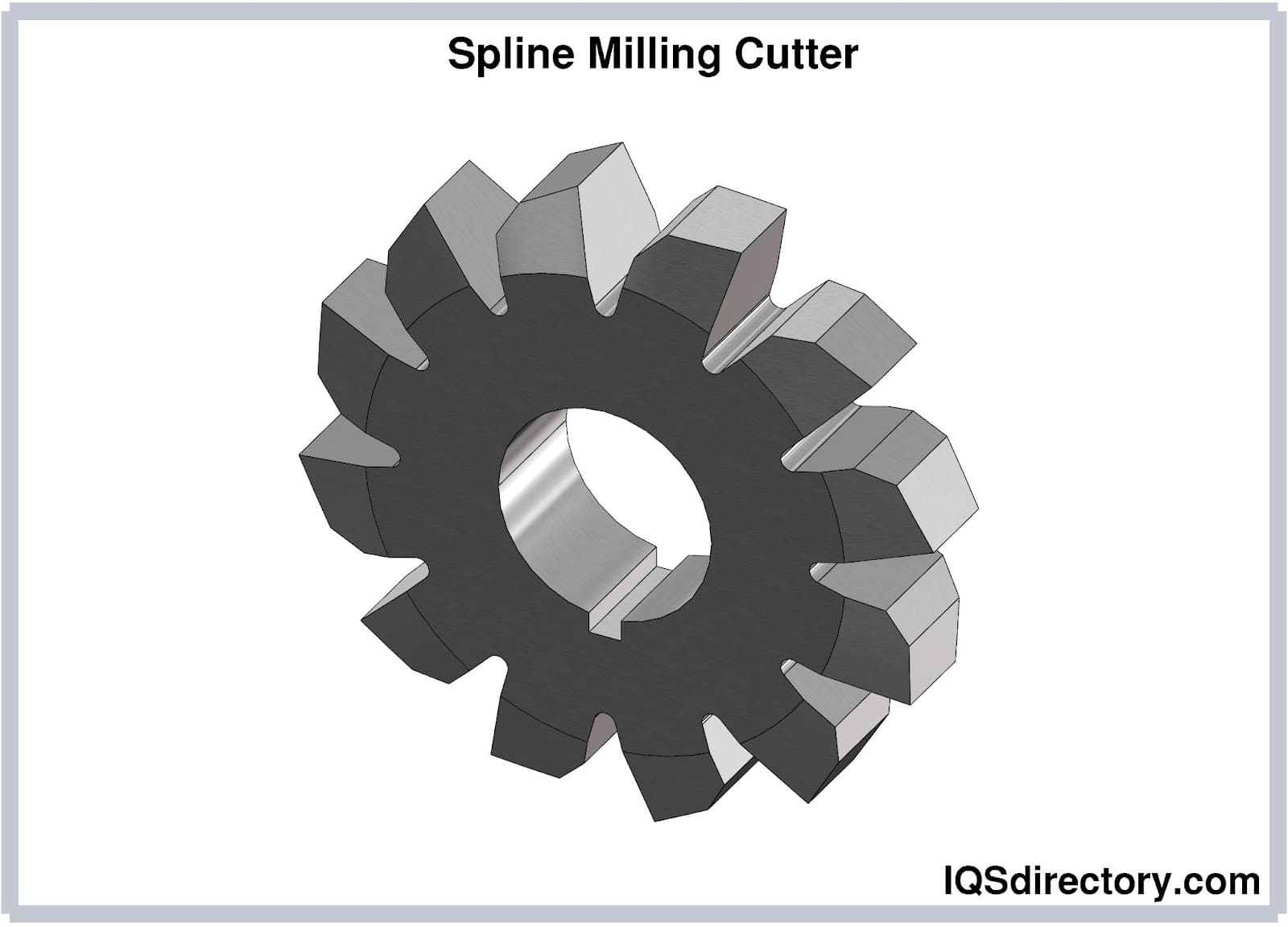

Milling

Serrations and parallel or involute splines are both capable of being machined. The intervals between the teeth are machined using a double- angle milling cutter intended to provide the proper spacing of a serration or parallel key-spline shaft. For involute splines, these gaps would be machined using a milling cutter that has the reverse form of the involute for that particular diametral pitch, pressure angle, and number of teeth. The index between teeth is provided by an index, dividing head, or CNC rotary table.

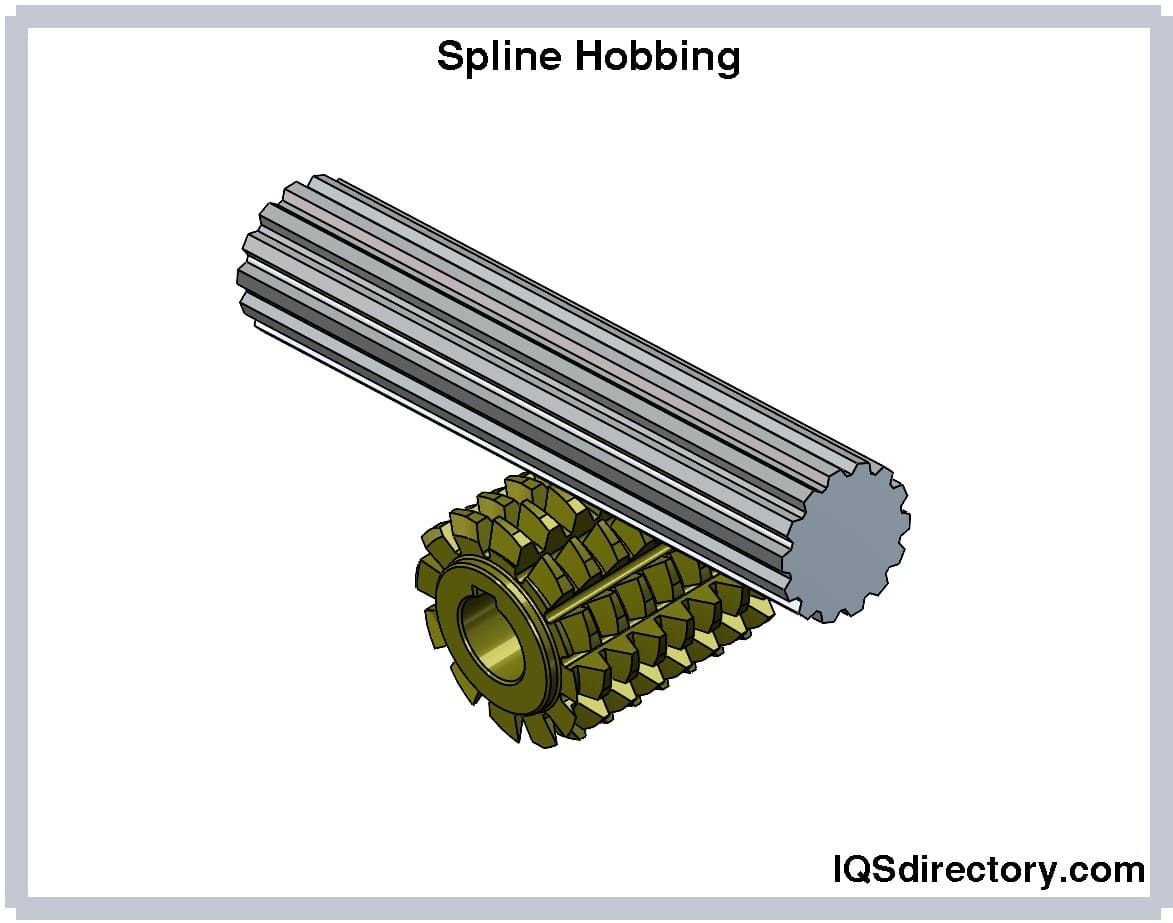

Hobbing

Hobbing is the process of generating teeth onto a material through the use of a hob, which is a rotating cutter device (that vaguely resembles a pine cone). The hobbing technique can be used to construct any form of external splines using a cylindrical hob with the desired spline's mating rack shape.

The ratio that the hobbing machine is geared or set to produce is determined by the number of starts (rows of cutting edges) on the hob and the number of teeth in the spline. The hob then "rolls" with the spline, much like a gear would roll with a rack. As it travels along the axis of rotation of the hob, material from the crevices between the spline teeth is removed by the hob's cutting teeth.

Shaping

Both internal and external splines can be created using spline shaping. The process centers around a shaper/cutter, which is a disc having a cutting edge on one face with a specific tooth count, diametral pitch, and pressure angle. The differential gear train or programmed ratio for the shaping machine is determined by the ratio of the number of teeth in the cutter and the number of teeth desired in the piece being worked.

The precise rotational ratio between the cutter and the job is determined by this ratio. Then, with both the cutter and the work rotating, the cutter is reciprocated along an axis parallel to the work. During the down-stroking motion, the cutter removes material from the work as they roll together (like a gear and pinion would) and creates teeth on the worked material as a result.

Broaching

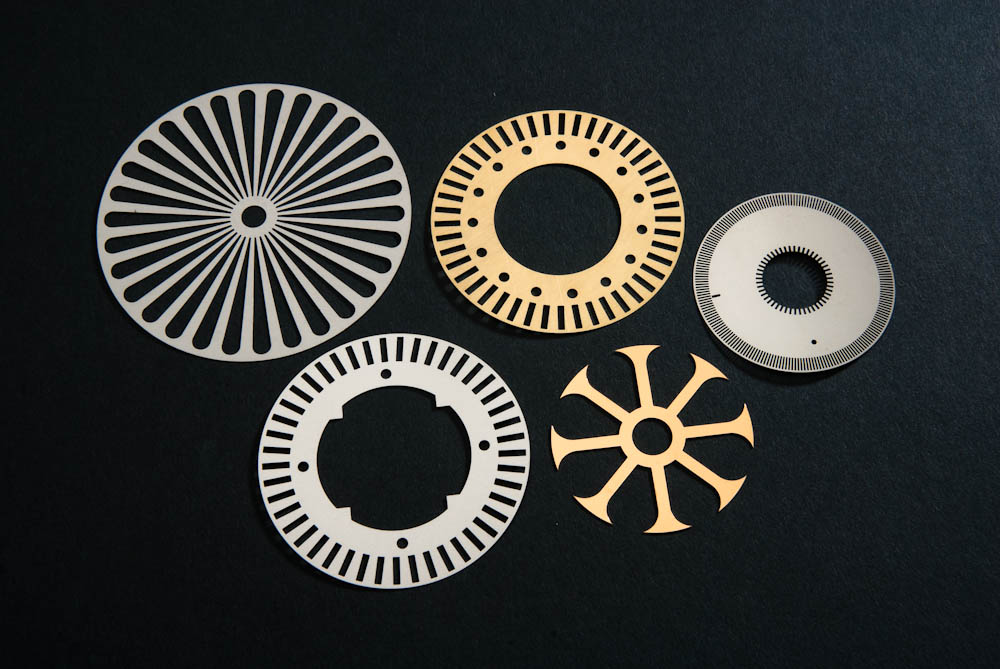

Broaching is a machining process that uses a sharp, toothed tool, known as a broach, to remove material from a workpiece. Only female (teeth facing inward) parts are created using this technique and these splines must be created in relationship to its intended male counterpart. With broaching, the tool must be the right shape and size to create the female spline that is intended.

The broach's beginning end has a smooth diameter that fits inside the workpiece's smooth bore. From this end of the instrument to the opposite end, there are numerous cutting edges along the length of the cutting instrument and these cutting edges are at specified, equal axial distances. This permits each cutting edge to achieve a certain chip load (thickness of material removed by a cutting edge per cut) as it is drawn or pushed through the blank. Each cutting edge produces a spline (row of teeth) that gradually increases in form. The final spline size is generated by the final rows of cutting edges as they exit.

Slotting

Slotting is typically used to produce internal splines and, although alternative techniques are frequently more effective, this method can also be utilized for exterior splines. Through the slotting process, a tool is utilized to mirror the spline's intended space. This tool is in-fed between a spline-producing machine’s various strokes and reciprocated along an axis that is parallel to the material to be worked. The cutting motion takes place on the downward stroke. Once the tool has reached its maximum depth, it is withdrawn to its initial position. This procedure is repeated until all the spaces have been machined and the job is completed.

Choosing the Proper Spline Cutting Supplier

To make sure you have the most constructive outcome when purchasing Spline Cutting from a Spline Cutting Supplier, it is important to compare at least 4 Companies using our list of Spline Cutting manufacturers. Each Spline Cutting Company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Spline Cutting business website using our patented website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple Spline Cutting businesses with the same quote.

Broaching

Broaching CNC Machining

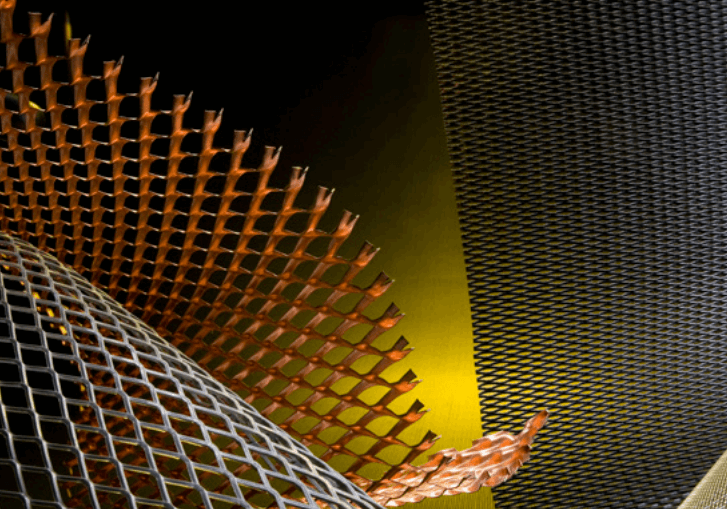

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

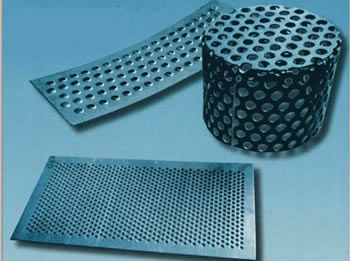

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

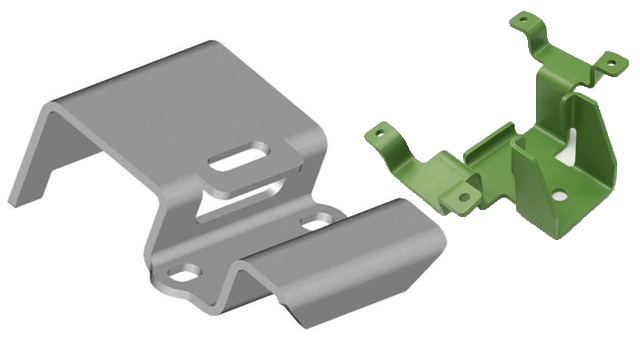

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services