Most broached products are produced in these facilities, when metal workpieces are broached internally or externally in high runs and large volumes. The broaching process is cost effective, easy and efficient because it is done with automated or CNC operated machinery that is either horizontal or vertical in orientation. Read More…

Pioneer Broach Company is premier vendor of quality rotary broaching cutting tools. We specialize in custom spline, serration and hexalobular shaped rotary or wobble broaches, and also offer a complete line of standard hex and square rotary broach tools. Our new rotary broaching toolholder is designed for all modern CNC machines, mills and lathes.

Apex Broaching Systems is a worldwide supplier of standard broaching machines, special purpose broaching machines, fixturing, automation, and cutting tools. We have over 69 years of innovative engineering, skilled craftmanship, quality manufacturing, assembly, and customer satisfaction. All of our products are made here in the USA. Contact us today and tell us how we can meet your demands!

Diamond Broaching Service LLC showcases its value to its customers and the industry through quality customer service. The new team of Engineers and Machinists continue to provide the same high quality broaching services that our customers have depended on for over 70 years. With over 400 Broaching Tools in our inventory, we can respond quickly to provide the following shapes in just about all...

Since 1981, Universal Broaching has made a name as a dependable broaching job shop that offers quality products, impeccable service & competitive pricing for all broaching needs, no matter the size of the run. We offer horizontal internal broaching, vertical surface broaching, blind hole keyseating, broach sharpening, reconditioning & repair, and engineering & manufacturing of broaches & fixtures.

More Broaching Job Shop Companies

The production broaching done at broaching job shops is an exceedingly positive broaching characteristic, since many work-pieces are machined at once and this process takes only seconds to complete.

Since broaching requires no secondary operations and the machining process is so short, producing high volumes of industrial products like pulleys, gears, sprockets and the threading on screws takes little time.

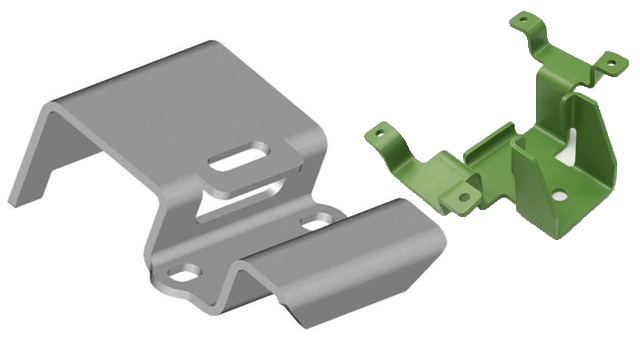

Broaching machines are considered special purpose machinery because they are confined to very limited capabilities; many can only produce one or two different product designs. For this reason, facilities that use broaching machines usually specialize in a certain type of broaching, including blind broaching, external broaching or rotary broaching.

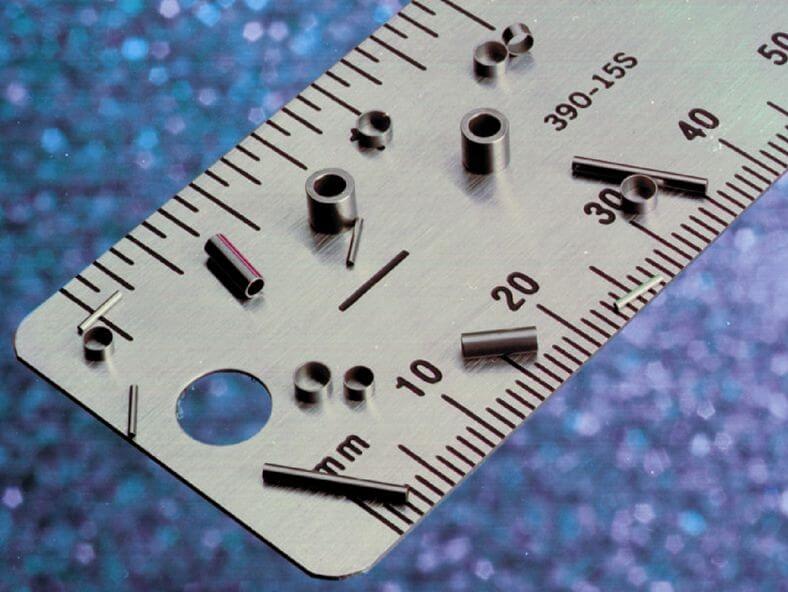

These processes machine work-pieces, usually made out of softer metals like aluminum, copper and brass, that when finished are used within the automotive, machinery, aerospace, commercial and military industries. Broaching machines produce several different shapes in metal, which alter the surface or are drilled straight through.

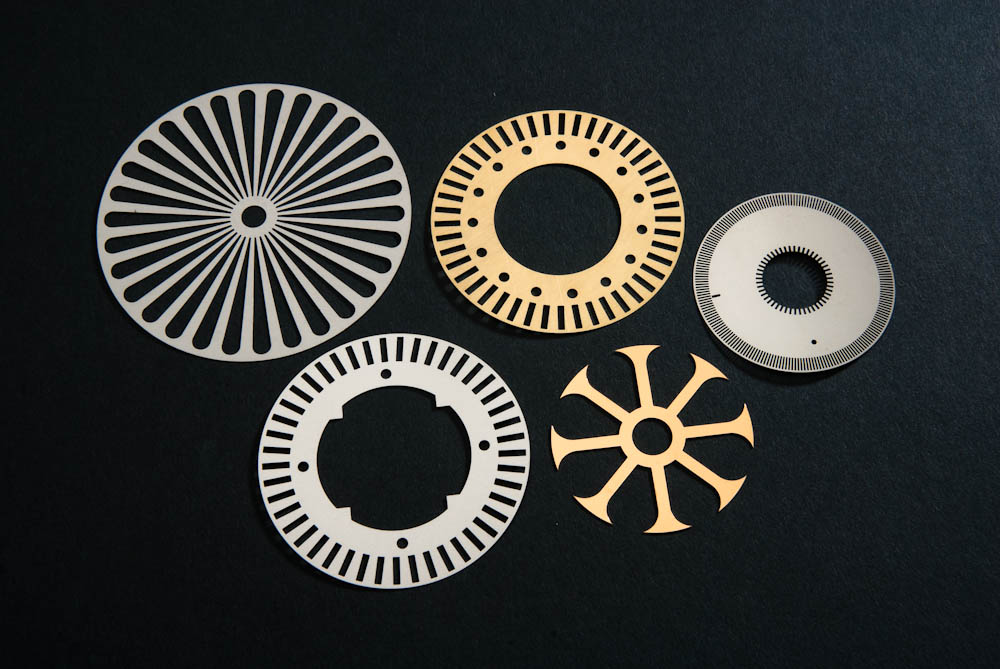

Types of shapes created by broaching machines include hexagonal, square, round, slots, splines and the most common cut, a hole with a keyhole-shaped profile called a keyway. Broaching is accomplished several different ways, including pull and push broaching. When a work-piece is pull broached, the broach tool, which is long and thin with successively larger teeth, is pulled through the part in a continuous motion. It can also be pushed through.

Rotary broaching is done on a lathe and the tool revolves at high speeds. Some broaching processes like pot broaching reverse the motion and while the tool remains stationary, the work-piece is moved with high force through it inside of a hollow housing called a pot.

Larger broaching job shops contain several of these machines, which are also able to stamp, cast and forge the work-pieces. While there are many different methods and styles of broaching, the main idea remains constant.

Every broaching machine, whether vertical or horizontal, contains one or more broach tools that contain teeth that cut out pieces of metal on the interior or exterior of the metal work-piece. They are automated and sometimes even part of a conveyor line system.

Broaching

Broaching CNC Machining

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

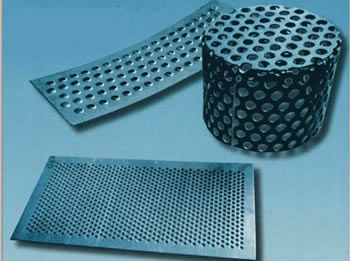

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services