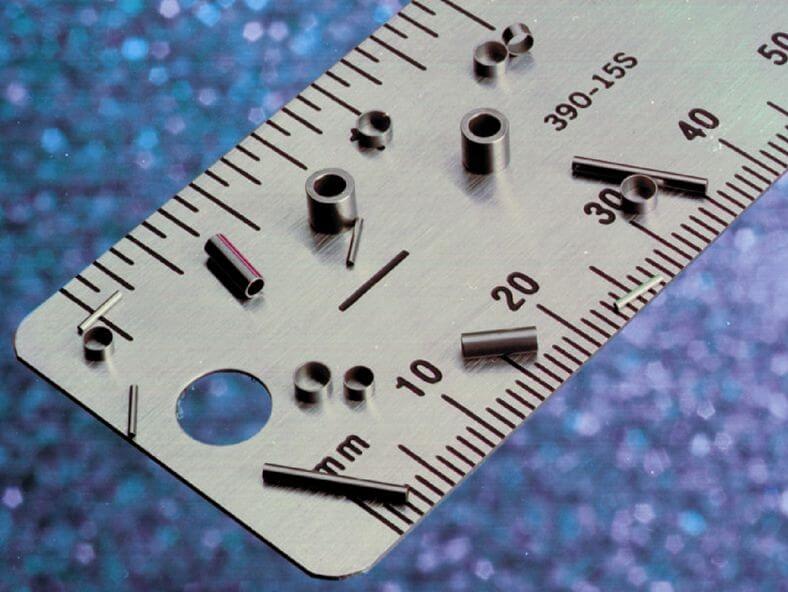

Broaching is a metalworking process that creates precision holes, slots, and contours in various materials such as metal, plastic, and composites. It is a highly efficient and accurate machining process used for over a century in manufacturing industries. Read More…

Pioneer Broach Company is premier vendor of quality rotary broaching cutting tools. We specialize in custom spline, serration and hexalobular shaped rotary or wobble broaches, and also offer a complete line of standard hex and square rotary broach tools. Our new rotary broaching toolholder is designed for all modern CNC machines, mills and lathes.

Apex Broaching Systems is a worldwide supplier of standard broaching machines, special purpose broaching machines, fixturing, automation, and cutting tools. We have over 69 years of innovative engineering, skilled craftmanship, quality manufacturing, assembly, and customer satisfaction. All of our products are made here in the USA. Contact us today and tell us how we can meet your demands!

Diamond Broaching Service LLC showcases its value to its customers and the industry through quality customer service. The new team of Engineers and Machinists continue to provide the same high quality broaching services that our customers have depended on for over 70 years. With over 400 Broaching Tools in our inventory, we can respond quickly to provide the following shapes in just about all...

Since 1981, Universal Broaching has made a name as a dependable broaching job shop that offers quality products, impeccable service & competitive pricing for all broaching needs, no matter the size of the run. We offer horizontal internal broaching, vertical surface broaching, blind hole keyseating, broach sharpening, reconditioning & repair, and engineering & manufacturing of broaches & fixtures.

More Broaching Job Shops Companies

Broaching originated as a way to make keyways in firearms. The automotive and aerospace industries later adopted it to manufacture precision parts with complex shapes and tight tolerances. The process has evolved with the development of new tools, machines, and techniques, making it one of the most efficient and accurate machining methods.

Types of Broaching

There are several types of broaching, many of which are detailed below.

Blind Broaching:

Blind broaching is a type of broaching used to create features like holes or slots that do not pass through the entire workpiece. It involves the use of a broach tool with progressively larger cutting edges, guided by a broach machine or fixture. The tool removes material up to a certain depth, leaving a blind or closed-end feature. Blind broaching offers precise and accurate results with tight tolerances and is commonly employed in industries such as automotive and hydraulic systems. It enables the creation of high-quality components efficiently, though it has limitations for extremely deep blind features or materials that are too hard or brittle. Overall, blind broaching is a valuable technique for producing closed-end features, contributing to the manufacturing of reliable and high-performance components.

Internal Broaching:

Internal broaching is a precise and efficient type of broaching used to create internal features such as holes, bores, keyways, or splines within cylindrical workpieces. It involves the use of a broach tool with progressively larger cutting edges, guided by a machine or fixture, to remove material and shape the internal feature. Internal broaching offers advantages such as high precision, tight tolerances, cost-effectiveness through single-tool multiple feature production, and good surface finish. It finds applications in automotive, aerospace, hydraulic, and pneumatic industries, among others. However, limitations include restrictions on depth based on tool length and suitability for extremely hard or brittle materials. Overall, internal broaching is a valuable machining method for achieving accurate and complex internal features in various components.

Surface Broaching:

Surface broaching, also known as flat broaching, is a machining technique used to create flat or contoured surfaces on a workpiece. It involves the use of a broach tool with multiple cutting edges that remove material from the surface of the component. Surface broaching offers advantages such as efficient machining of large surface areas, high accuracy, and tight tolerances. It finds applications in industries such as gear manufacturing and the creation of splines, slides, guide rails, and precision blocks. However, surface broaching is most effective on flat or slightly contoured surfaces and may not be suitable for highly complex shapes. Overall, surface broaching is a valuable method for achieving precise surface finishes in manufacturing processes.

Keyway Broaching:

Keyway broaching is a machining technique used to create precise keyways in rotating components, such as shafts and hubs. It involves the use of a specialized broach tool with cutting teeth that gradually increase in size. The tool is guided through the workpiece to remove material and form the keyway shape. Keyway broaching offers advantages including efficient and accurate keyway creation with tight tolerances. It finds applications in automotive, industrial machinery, and power transmission equipment. However, limitations exist in terms of dimensional restrictions and suitability for extremely hard or brittle materials. Overall, keyway broaching is a valuable method for achieving reliable keyway connections in various industries.

Rotary Broaching:

Rotary broaching, also known as wobble broaching, is a specialized machining technique used to create intricate polygonal or non-circular shapes on the surface of a workpiece. It involves using a specially designed broach tool with offset cutting edges that produce a wobbling motion when rotated. Rotary broaching offers advantages such as the ability to create complex shapes with high precision and repeatability. It finds applications in industries such as automotive, aerospace, and precision component manufacturing. While it excels at producing shallow features on the workpiece surface, achieving deep profiles may be challenging. Overall, rotary broaching is a valuable method for achieving unique and precise profiles in various industries.

Pot Broaching:

Pot broaching, although not a widely recognized term, refers to a specialized form of internal broaching used to produce components with non-linear internal holes or cavities. It involves the use of a specially designed broach tool to match the desired non-linear shape and a workpiece resembling a “pot.” The broach tool is guided and driven into the workpiece to remove material and create the intricate internal shape. Pot broaching allows for the production of complex internal features, but it is a highly specialized method that requires expertise and customized tooling.

Helical Broaching:

Helical broaching is a specialized form of broaching used to create helical features such as threads or worm gears on cylindrical workpieces. It involves using a specially designed broach tool with cutting edges configured to form the desired helical shape. The tool is guided and rotated while being pushed or pulled through the workpiece, resulting in the precise and efficient production of helical profiles. Helical broaching offers advantages such as accurate and uniform helical features with tight tolerances, and it finds applications in industries like automotive, aerospace, and machinery manufacturing. However, the capabilities of the broach tool determine the depth and pitch of the helical feature. Overall, helical broaching is a valuable machining technique for creating precise and cost-effective helical features for rotational motion transfer and threaded connections.

Overall, these different types of broaching allow manufacturers to produce a wide range of components with varying shapes, sizes, and features. The choice of broaching method depends on the specific application, the material, and the required accuracy and precision of the finished product.

Laws and Regulations Related to Broaching

Broaching machines and tools are subject to various laws and regulations to ensure safety and compliance. In the United States, the Occupational Safety and Health Administration (OSHA) sets standards for the safe operation of broaching machines and tools, including requirements for machine guarding, personal protective equipment (PPE), and employee training. These regulations aim to prevent accidents, injuries, and occupational hazards associated with broaching operations. Additionally, environmental regulations such as the Clean Air Act and the Clean Water Act may apply to the operation of broaching machines, ensuring proper waste management, emissions control, and environmental protection. Compliance with these laws and regulations is essential to maintain a safe working environment, protect employees’ health and well-being, and minimize the impact of broaching operations on the environment.

Limitations of Broaching

While broaching is a highly efficient and accurate machining process, it has some limitations. Broaching is not suitable for materials that are too hard or brittle, as they can cause the broach tool to break. Broaching is also not ideal for creating features with varying depths because it requires a separate tool for each depth.

Benefits of Broaching

Broaching offers several benefits, including high accuracy and precision, fast machining times, and versatility. It is also cost-effective as it can produce multiple features with a single tool and requires minimal finishing. These benefits are better explained below.

High Accuracy and Precision:

Broaching is a highly accurate machining process that can produce precise and intricate features with tight tolerances. As a result, broaching can produce features with complex shapes and contours that are difficult to achieve using other machining methods.

Cost-Effectiveness:

Broaching can produce multiple features with a single tool, reducing the time and cost associated with manufacturing. Broaching is a cost-effective machining method as it can produce multiple features with a single tool and requires minimal finishing.

Fast Machining Times:

Broaching is a highly efficient machining process that can rapidly remove material and create features in a single pass. Compared to other machining methods, broaching offers faster production times, leading to increased productivity and shorter lead times.

Versatility:

Broaching is a versatile process that can be applied to various materials, including metals, plastics, and composites. It can be used to create a wide range of features such as holes, slots, gears, splines, and keyways, making it adaptable to diverse manufacturing needs.

Surface Finish Quality:

Broaching can achieve excellent surface finishes on components. The cutting action of the broach tool results in smooth surfaces with minimal burrs or roughness, reducing the need for additional finishing operations.

High Repeatability:

Broaching offers excellent repeatability, ensuring consistent results across multiple components. This makes it ideal for high-volume production runs where uniformity and consistency are critical.

Enhanced Part Strength:

Broaching can enhance the strength and integrity of components by creating precise features with proper fits and interlocking profiles. This is particularly important in applications where torque transmission, load-bearing capabilities, or structural integrity are essential.

Design Flexibility:

Broaching allows for design flexibility, enabling the production of intricate and customized features. It supports the creation of unique shapes, profiles, and contours to meet specific design requirements.

Overall, broaching provides numerous benefits, including high accuracy, fast machining times, cost-effectiveness, versatility, excellent surface finish quality, efficient material removal, repeatability, enhanced part strength, and design flexibility. These advantages make broaching a preferred choice in various industries where precise, complex, and high-quality components are required.

Applications of Broaching

Broaching has a wide range of applications across various applications and industries. Broaching is used in hydraulic systems to create internal features such as ports, bores, and channels in components like cylinders, valves, and fittings, ensuring efficient fluid flow and system functionality. Broaching is also employed in pneumatic systems to produce internal features such as air passages, valve seats, and ports in components like pneumatic cylinders, valves, and actuators, facilitating optimal air flow and system performance. In the automotive sector, it is used for manufacturing gears, transmission shafts, and steering system parts. In aerospace, meanwhile, broaching is utilized to create critical components like turbine blades, engine parts, and landing gear components. The medical industry also employs broaching for producing surgical instruments, orthopedic implants, and dental components. In the consumer goods sector, likewise, broaching is used to manufacture locks, keys, hand tools, and hardware components. Additionally, broaching finds application in the defense industry for producing components used in military equipment.

Broaching also plays a role in other industries. In the oil and gas sector, it is used for manufacturing drilling tools, pumps, valves, and couplings. The renewable energy industry also employs broaching in the production of components for wind turbines, solar power systems, and hydroelectric power plants. In the electrical and electronics industry, furthermore, broaching is used for creating connectors, terminals, and contacts. Finally, the tool and die industry relies on broaching for manufacturing cutting tools and dies, while the railway industry utilizes it for producing railway components like axles, wheel hubs, and traction system parts. Overall, broaching serves as a versatile, precise, and efficient machining method for the production of complex components across a wide range of industries.

Choosing the Right Broaching Company

To ensure you have the most constructive outcome when choosing a broaching company, it is important to compare several businesses using our directory of broaching companies. Each broaching company has a business profile page highlighting their areas of experience and capabilities, along with a contact form to communicate with the business for more information or request a quote. Review each broaching company website using our proprietary website previewer to quickly learn what each business specializes in. Then, use our simple RFQ form to contact multiple broaching companies with the same form.

Broaching

Broaching CNC Machining

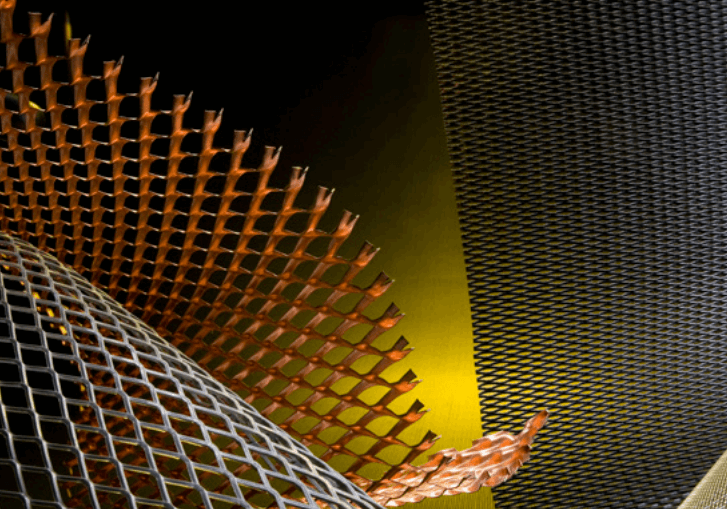

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

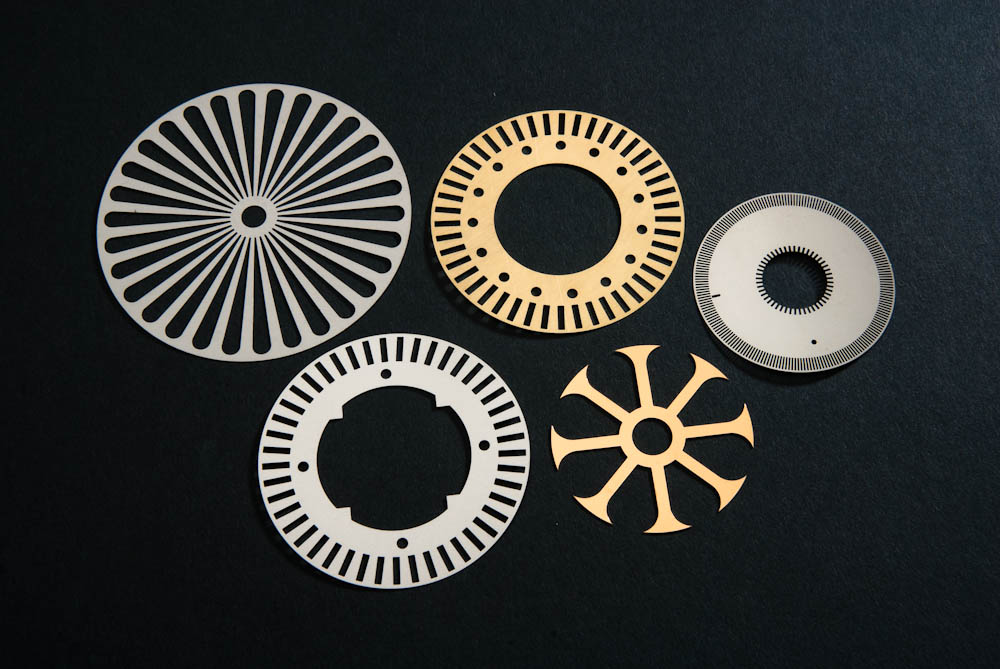

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

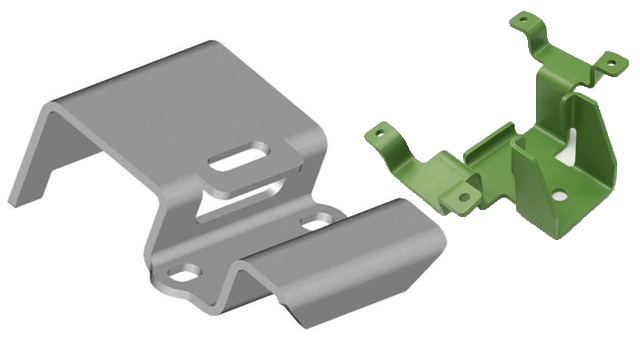

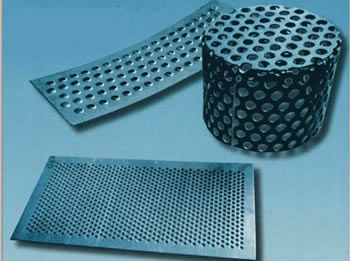

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services