Pot broaching is considered an external method because it doesn’t push the tool through the entire work-piece to form a hole, but rather alters the outside edges. It is considered the inverse of an internal broach and can only be used on cylindrically shaped work-pieces. Pot broaches get their name from the hollow fixture that holds the broach tools. It is a pot-like casing with a hole in the middle that holds multiple broaches over the entire length. Read More…

Pioneer Broach Company is premier vendor of quality rotary broaching cutting tools. We specialize in custom spline, serration and hexalobular shaped rotary or wobble broaches, and also offer a complete line of standard hex and square rotary broach tools. Our new rotary broaching toolholder is designed for all modern CNC machines, mills and lathes.

Apex Broaching Systems is a worldwide supplier of standard broaching machines, special purpose broaching machines, fixturing, automation, and cutting tools. We have over 69 years of innovative engineering, skilled craftmanship, quality manufacturing, assembly, and customer satisfaction. All of our products are made here in the USA. Contact us today and tell us how we can meet your demands!

Diamond Broaching Service LLC showcases its value to its customers and the industry through quality customer service. The new team of Engineers and Machinists continue to provide the same high quality broaching services that our customers have depended on for over 70 years. With over 400 Broaching Tools in our inventory, we can respond quickly to provide the following shapes in just about all...

Since 1981, Universal Broaching has made a name as a dependable broaching job shop that offers quality products, impeccable service & competitive pricing for all broaching needs, no matter the size of the run. We offer horizontal internal broaching, vertical surface broaching, blind hole keyseating, broach sharpening, reconditioning & repair, and engineering & manufacturing of broaches & fixtures.

More Pot Broaching Companies

This process has largely replaced hobbing, which is a milling process that fabricates gears, splines and sprockets.

Pot broaching requires complex tooling and fixtures, meaning it is a rare process, but the main method of manufacturing gears that have external teeth splines cut into their outside edges. They are also able to cut involute and straight splines, as well as external flats and slots. Pot broaching is done on vertical machines and is often an automated process.

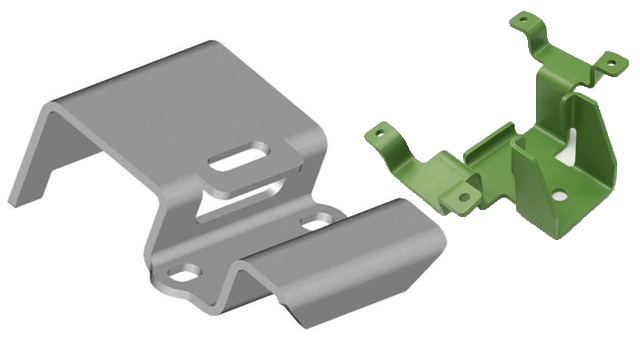

This method of broaching gets its name from the fixture where the broaches are mounted inside. The tools are arranged in the hollow holder, which resembles a pot, and the tool assembly passes over the work-piece to all of its external surfaces. The broach is usually held stationary while one or more work-pieces are continuously pushed into the hollow fixture and through the linear broach tools.

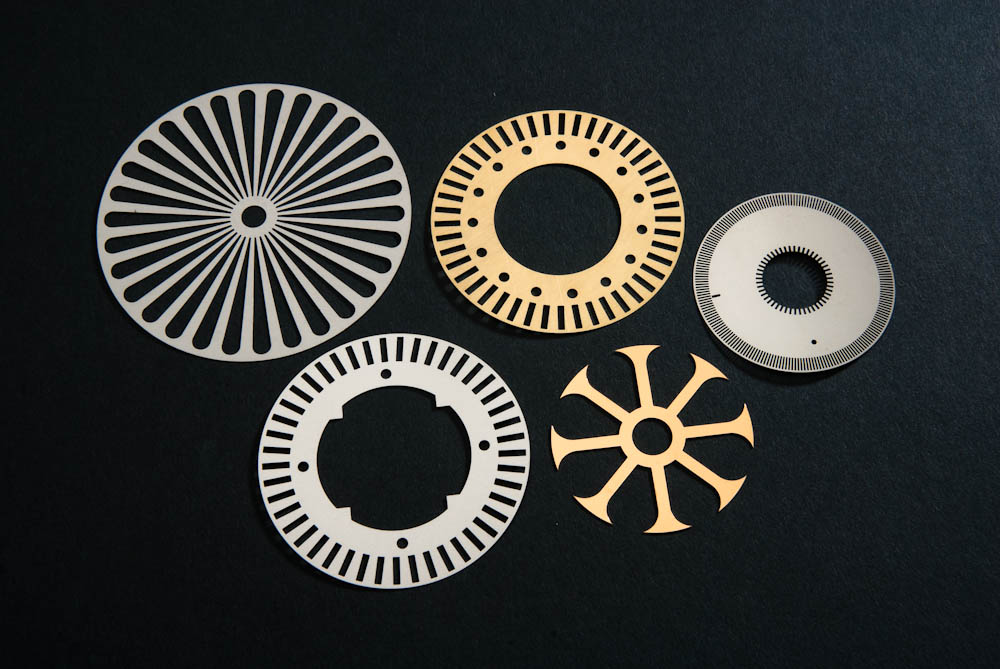

These broaching machines have individual formed broach inserts called sticks, multiple ring broaches or a combination of both types. Pot broaching is often used for spiral broaching, where the part is turned continuously through a spiral-shaped tool in order to produce external threading on fasteners like screws. There are three types of broaching tools that have an internal cutting tool configuration-ring, stick or a combination of both.

When single or multiple work-pieces are pulled or pushed through the bore (hole) of the pot broach, which doesn't ever move, the tools alter their outside diameters. The broach tools must be sized according to the design of the work-piece.

Broaching

Broaching CNC Machining

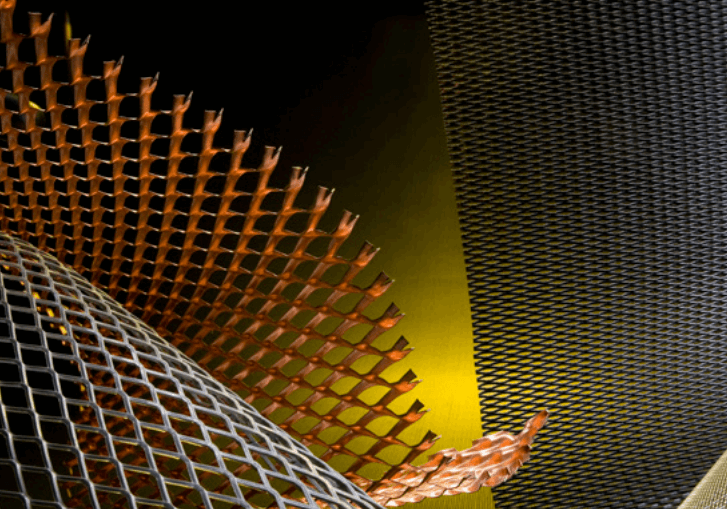

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

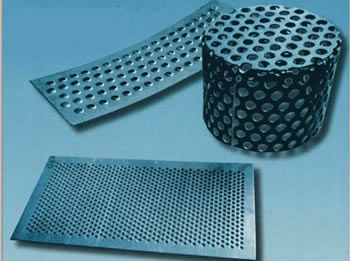

Metal Fabrication Perforated Metals

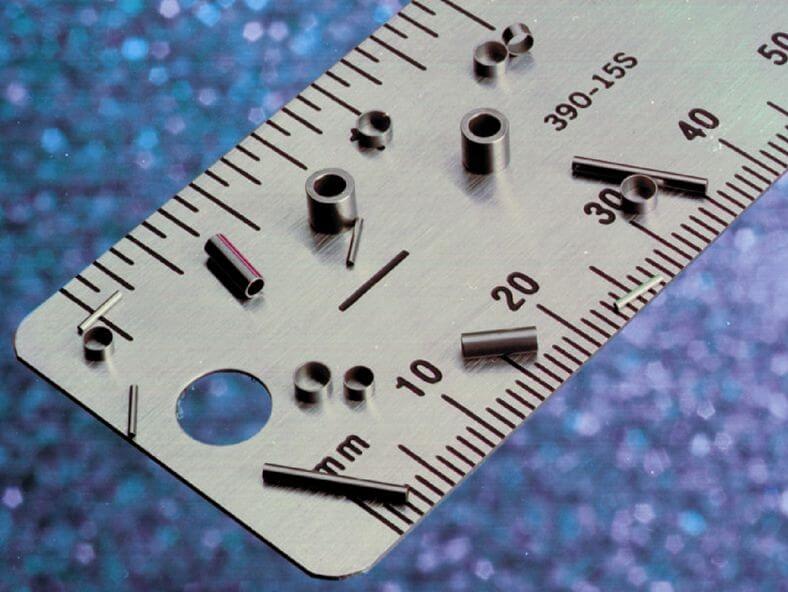

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services