Keyseaters are also known as keyway broaching machines, keyway cutters and keyseat cutters. They are a subcategory of internal broaching, which is a specific type of broaching that puts a hole from one surface side of a material through to the other side of the material, unlike blind broaching, which only involves surface work. Read More…

Pioneer Broach Company is premier vendor of quality rotary broaching cutting tools. We specialize in custom spline, serration and hexalobular shaped rotary or wobble broaches, and also offer a complete line of standard hex and square rotary broach tools. Our new rotary broaching toolholder is designed for all modern CNC machines, mills and lathes.

Apex Broaching Systems is a worldwide supplier of standard broaching machines, special purpose broaching machines, fixturing, automation, and cutting tools. We have over 69 years of innovative engineering, skilled craftmanship, quality manufacturing, assembly, and customer satisfaction. All of our products are made here in the USA. Contact us today and tell us how we can meet your demands!

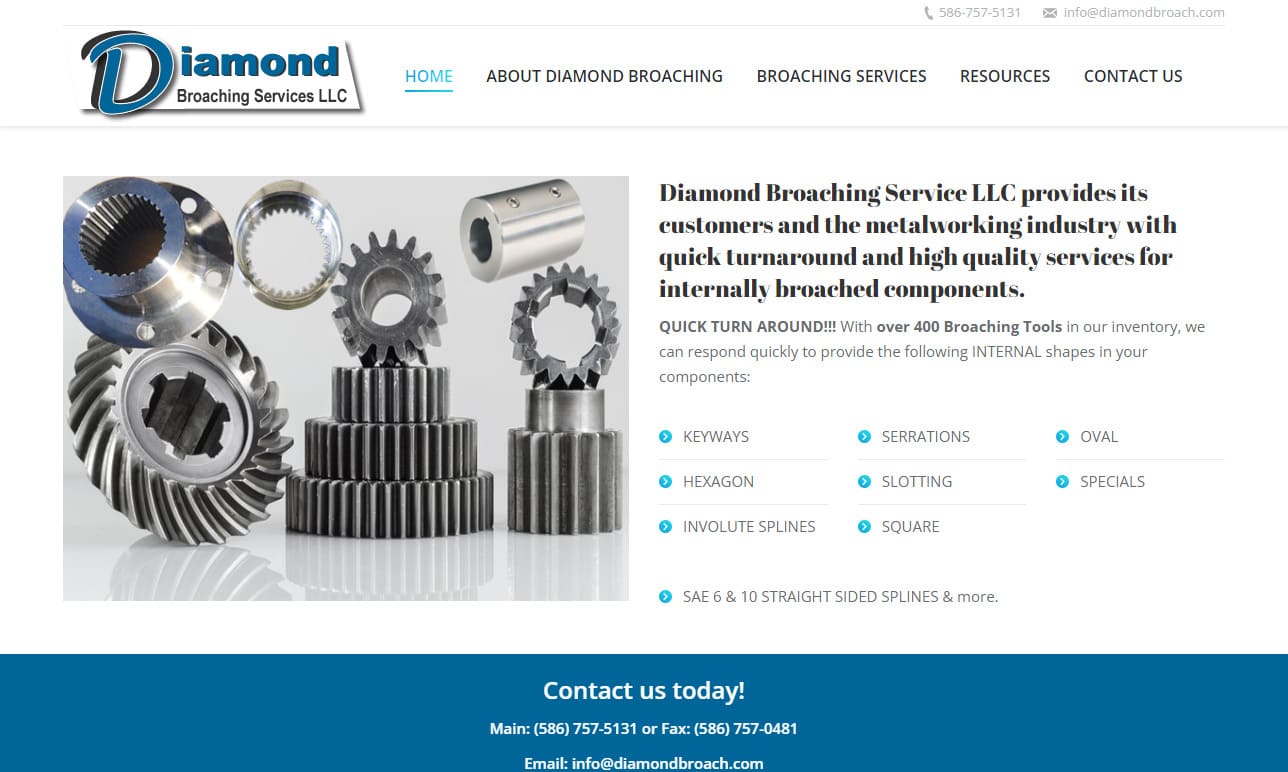

Diamond Broaching Service LLC showcases its value to its customers and the industry through quality customer service. The new team of Engineers and Machinists continue to provide the same high quality broaching services that our customers have depended on for over 70 years. With over 400 Broaching Tools in our inventory, we can respond quickly to provide the following shapes in just about all...

Since 1981, Universal Broaching has made a name as a dependable broaching job shop that offers quality products, impeccable service & competitive pricing for all broaching needs, no matter the size of the run. We offer horizontal internal broaching, vertical surface broaching, blind hole keyseating, broach sharpening, reconditioning & repair, and engineering & manufacturing of broaches & fixtures.

More Keyseater Companies

These machines function by way of a topside support and guiding system, which ensures that the cuts are clean and precise. The cut comes from below the work-piece and cuts on the down stroke. The guiding system, usually a vise or clamp, keeps the material in place, and is either fed through the cutter manually, if the table is permanent, or if the table is moveable this happens automatically.

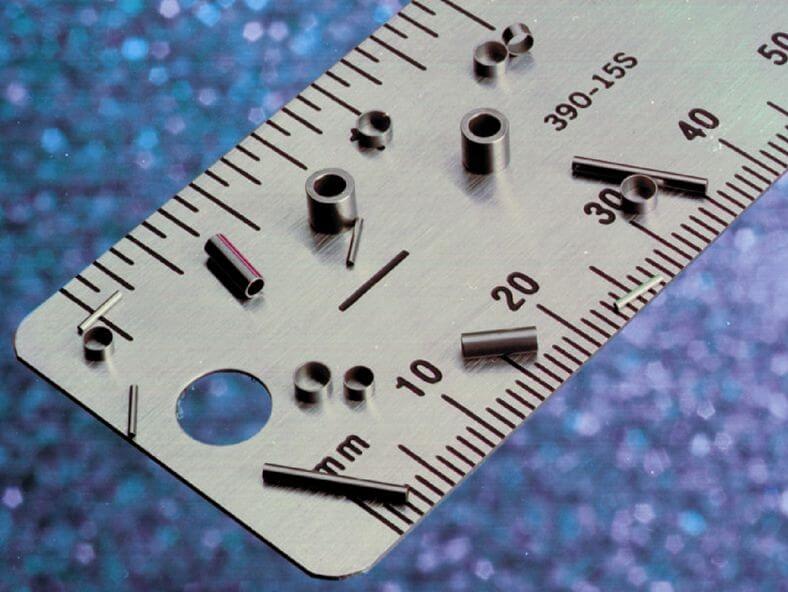

The piece being cut moves horizontally, while the keyseater cutter moves vertically. Although keyseaters are best known for cutting key holes, they are also capable of making other cuts, including cuts that do not fully penetrate. Examples of other products are tools like wrenches, fasteners and bushings.

The materials keyseaters commonly pierce through are metal, wood and plastic. Keyseating machines are almost always CNC run machines. Any object that has a lock requires the skills and operations of a keyseater.

Because of the varied materials that keyseaters must cut through, the material that they are made out of must be equally tough, if not more so. Diamond, cobalt, carbide and steel are all common materials for keyseaters, the first three being particularly effective for high speed machines. Coating is another necessity for keyseating machines, since the material is not about being corrosive resistant but doing the best job of keyseating consistently.

Therefore, coating processes such as anodizing, plasma spraying, ion plating, thermal spraying and electroless plating all increase the tool's hardness and resistance to abrasion, as well as making them sleeker. All of these characteristics contribute to the workable life of the keyseater.

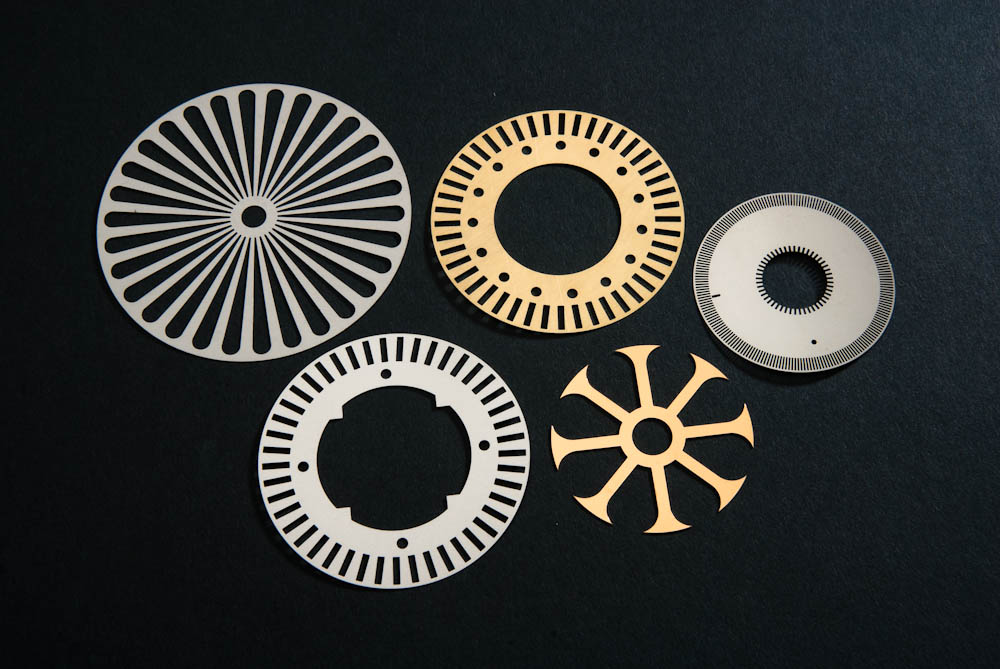

Broaching

Broaching CNC Machining

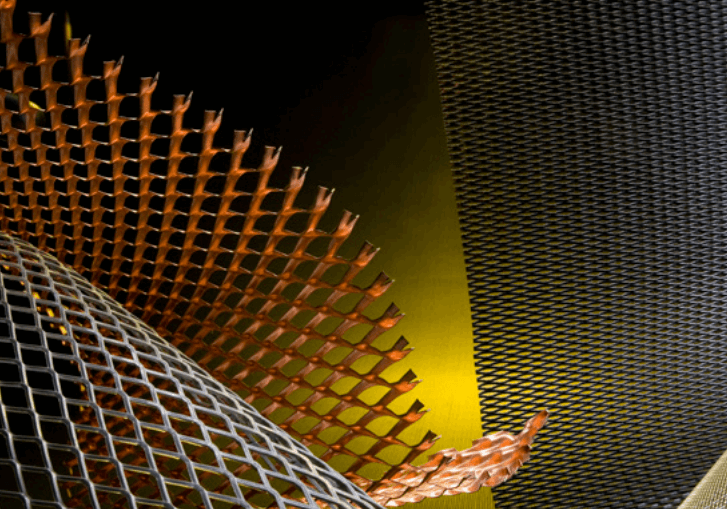

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

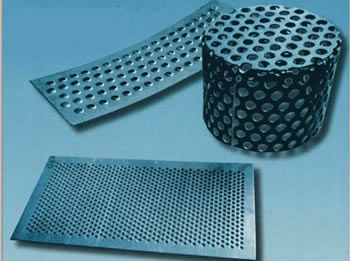

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

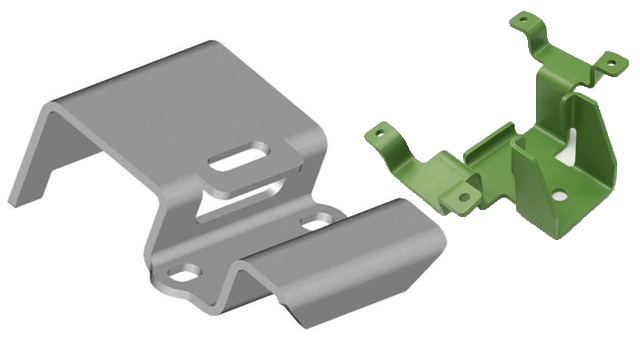

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services